Intro

This project was inspired by (Dziugan et al. 2016):

Medium prepared from raw sugar beet juice and sterilized by ozonation is suitable for use in fermentation processes.

Instead of the traditional PBW washes and obsessive bleaching in homebrewing, I decided to test whether ozone can be used for effective and simple sterilant.

Procedure

- combine all ingredients except yeast in fermenter

- no need to sterilize anything

- bubble ozone through media for 20-30 minutes

- let media rest while ozone dissipates (10-20 minutes)

- add yeast

- ferment as usual

Work Log

13 Dec 2021

Woot. I racked the cider today.

Final S.G. 1.000 (!)

9.6% ABV with 100% conversion.

It is a little flat but deliciously tart. That comes from my poor choice of apples.

Autoclaved a cup of cherry wood chips after soaking in water for about 10 minutes. The small amount of red liquid that pooled in the jar was added directly to the cider. The wood chips were then broiled until smoking and added to the cider.

So we will have some cherry and smokey hints. I would like to do some speed ageing with ultrasonics, but I don’t think that that it possible with my dinky sonicator. It would take about 14 hours to process the whole batch.

Autoclaving might be a possibility. At least it would be significantly safer than my previous attempt with distilled spirits.

Perhaps I should back-sweeten with sugar or even molasses? Target SG 1.004-1.014.

08 Dec 2021

The bubbles have slowed considerably (t+72 hours). One bubble every 10 seconds now. The first day gave 1 bubble every second or so. This is somewhat worrying.

I suppose the starter culture sped things up a bit. Most fermentation takes 12-24 hours to show. Mine was visible at t+6 hours.

05 Dec 2021

Brewing some hard cider for a New Year’s party.

A “sink full” of apples from the store.

- 6 lbs Winesap

- 9 lbs granny smith (local)

- 5 lbs granny smith (nonlocal)

- 6 lbs Mcintosh

The choice was mostly due to what was available at my local grocery store.

Apples were washed in the sink with a splash of bleach. Cut into quarters and chopped in a food processor. The grater attachment broke after the first couple apples so I was forced to use the less effective chopper attachment.

Apple mush was squeezed in a nylon nut bag to remove most of the juice. The juice was added directly to the fermentation vessel (13L pyrex) containing 1 tsp pectic enzyme.

The pomace was emptied into a stainless stock pot with more enzyme and about 1/2 c table sugar. I’ll let this sit for a while to break down more of the apple bits before pressing with a 1.5 ton hydraulic press I made last night.

About six liters of juice was collected from the first pressing.

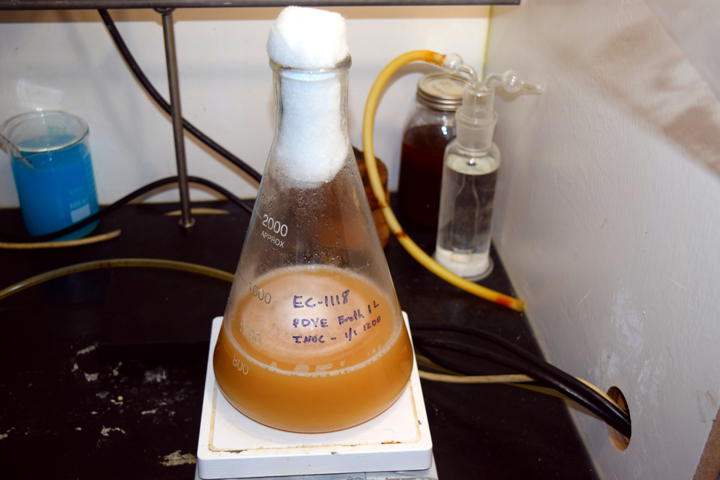

Some 3 year old cider yeast was added to a 1L flask with 450ml of juice, 0.4g DAP + urea yeast nutrient, and about 1 tsp table sugar. After 1 hr, activity was confirmed by the expanding foam on top.

Added 6g yeast nutrient to main fermenter.

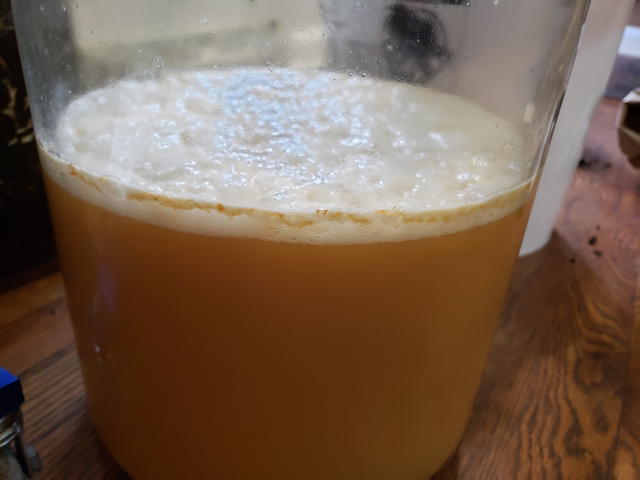

The starter culture is producing hella bubbles.

Recovered an additional 1 L from press. Kind of abysmal, but I’m tired of pressing apples. That brings the total volume to around 7 liters.

1.056 SG (~146 g/L dissolved sugar)

Target: 1.070 SG (182 g/L)

Add 36 g/L table sugar (total ~250g)

Final 1.072 SG.

Pitched yeast starter at about 6 hours of pre-fermentation.

Bubbling started about 4 hours after pitching. Nice.

11 Feb 2020

The sugar wash experiment has ceased producing gas. I think it is time to see the results. Distillation of 1L of wash is proceeding as I write.

About a week ago I oxygenated the wash for about 30 minutes. Just a simple airstone and air pump. I have also added a few pinches of ammonium sulfate and masterblend fertilizer along the way. All of this supplementing could have come to late, though.

…Sooooo the bp of the wash is 97.8C. That means the alcohol concentration is somewhere around 2.5%. So that was a waste.

Although, the s.g. is still about 1.097. I could try another packet of yeast. The mash doesn’t smell bad or anything.

25 Jan 2020

My sugar wash has not been producing very much CO2. From day 1, CO2 bubbling wash about once per second (a couple ml per second). This is not what I was expecting. I kept thinking that I had missed primary fermentation in the first day or two or there was some contamination or something. The more I thought about it, however, the more I realized how little nutrient I had actually added to the fermenter.

One liter of PDYE broth doesn’t have much. Certainly not enough nitrogen to supplement and entire 38 liters. So I decided to add some ammonium sulfate (~1tsp). Phosphate would have been better, but I don’t have any. I also added a pinch of Masterblend tomato fertilizer that contains chelated minerals. We will see in the next day or two what the CO2 effluent rate is.

The next run will have to include a smack-pack of turbo yeast or a lot more research into proper yeast nutrient. Considering that a 6 gallon turbo yeast pack is less than $10, I think the former is the best option.

02 Jan 2020

I did another sugar wash today starting from about 38 liters of 1.116 s.g. wash. I did not sterilize this time with ozone. I did, however, use a 1L PDYE broth starter culture from EC-1118 yeast, so even a high microbial load will be overwhelmed by a few hundred billion yeast cell in no time. I also added a little mineral oil to control foam.

From a s.g. of 1.116, the max alcohol content is about 15%. I will probably recover somewhere between 5 and 6 liters of pure ethanol. The cost of all the ingredients is right around $10. Almost all of that cost is for sugar (25 lbs for $8). The time investment for distillation is really where the cost is.

10 Jun 2019

This weekend I finally got around to using the strawberry wine with mixed results. It is hard to tell what people actually think of a wine when you ask them directly. They are always worried about offending you or hurting your feelings. One common response was that it tasted very alcoholic. When I tested the density, however, I only got about 8-9% ethanol. I suppose there could be dissolved solids that increased the density, throwing off the calculation. I also learned that not filtering the strawberry pulp before fermentation can increase the pungent aromatics that make a wine taste bad… next time.

Distilled some brandy from the strawberry wine. I don’t have a copper still, so I improvised with a short section of glassware stuffed with 1/4 inch copper raschig rings. Just a few inches of packing in total. It was probably equivalent to a one or two plate reflux condenser.

I discarded the “foreshot” and kept going until the temperature climbed to around 100C. The resulting ~240ml was slightly cloudy and smelled strongly of alcohol. I think the cloudiness is due to dissolved essential oils. It had a density of 0.9276 g/ml giving roughly 42% ethanol concentration.

I don’t have a corker handy, so I will probably distill the remainder just so it is stable.

31 Mar 2019

Filtered the wine through a “nut bag” to clarify. The carboy is only about 2/3rds full so I purged it with CO2 before sealing it again. The CO2 was generated by the reaction of magnesium sulfate and baking soda. The wine tastes pretty good after a quick decantation. I think I can call this a successful fermentation. Ozone works. I will bottle the wine so it can finish sometime in the next few weeks. Whenever I get a chance.

03 Mar 2019

Racked the wine. Tastes like wine…

28 Feb 2019

Strawberry wine is going well. It has almost finished fermenting. I had some trouble with foaming so I added 5-10ml mineral oil. It worked great. During the fermentation I swirled the carboy to mix the strawberry chunks. Currently the bubbling is once per second. Down from 2-3 per second at the peak of fermentation.

Unlike the fast-ferment sugar wash I did for lab grade ethanol a few months ago, the effluent gas from this wine doesn’t smell that bad. A slightly fruity and sweet number with a bit of alcohol. I’m perfectly fine leaving it on the dining room table to ferment in the open.

20 Feb 2019

Strawberry wine:

- 6kg trimmed strawberries

- 3.6kg sugar

- EC-1118 yeast

- tap water to make ~5gal

I didn’t sterilize anything or obsessively clean anything prior to use. I washed my hands. The carboy was previously stored with ~50ml of 95% ethanol inside to keep it clean. The strawberries were trimmed by removing the stems and any obvious damaged parts. They even sat at room temperature for 24hrs or so while prepped everything else. Some of the boxes may have been knocked on the floor by a cat.

I have no idea what the concentration of ozone is in the mini generator I pulled from a water cooler. It smells like ozone: that’s all I know.

I will know in a few days whether the ozone worked by the smell of the effluent.

Bibliography

Dziugan, Piotr, Maria Balcerek, Michal J. Binczarski, Dorota Kregiel, Marcin Kucner, Alina Kunicka-Styczynska, Katarzyna Pielech-Przybylska, Krzysztof Smigielski, and Izabela A. Witonska. 2016. “Ozonation as an Effective Way to Stabilize New Kinds of Fermentation Media Used in Biotechnological Production of Liquid Fuel Additives.” Biotechnology for Biofuels 9 (July). https://doi.org/10.1186/s13068-016-0574-2.