Work Log

07 Mar 2022

Water sterilizer

This prebuilt LED UV sterilizer uses 265-280 nm leds, quartz and polycarbonate construction, 1 liter per minute flow rate, 60mW radiant flux, and consumes 3-5 watts at 24 volts.

It has a continuous operating lifetime of 1,000 hours (10,000 hours when used only when water is flowing).

The 6 lpm model has a radiant flux of 200 mW, and consumes 18-23 W.

Low pressure mercury lamps have a typical efficiency of about 40% with a 9-14,000 hour lifetime.

So mercury lamps are more efficient, cheaper by a long shot, and last just as long, if not longer than UVC LEDs.

UVA LEDs on the other hand, are way better. This one has about 40% efficiency. The average lifetime is not listed, but 0/10 failed after 1000 hours in the high temperature condition, so that’s a good sign.

UVA can be used to disinfect hydroponic solutions. UVA is also less likely to degrade metal chelates.

Although… slow sand filtration seems cool. (???)

- 100-300 l/m2h

The paper above uses 8" (20cm) ID pipe, 217 cm tall. It used a 10W pump to move 5.6lph (180 l/m2h). That would be enough for one or maybe two dutch buckets and fast-draining media (3-5lph). Maybe you could get away with more if using drip irrigation and slow media like coir:perlite (1-2 lph). But that increases the risk of oxygen deprivation.

That’s the intermittent rate of application… Most drip systems only run 10-20% duty cycle. Actual water requirements for rockwool systems are somewhere around 100ml per plant per irrigation with a total of 1-2 liters per day.

Slow sand filters typically require constant flow rates and usually use water head as a means to control flow. That requires a secondary holding tank that slowly fills at a rate of 5 liters per hour but dispensed intermittently at a much faster rate.

PVC pipe of that size is expensive. I don’t need to support the pressure that PVC is designed for. Just the weight of the filter media.

Packed, wet sand has a density of about 2000 kg/m3. Call it 2500 for saturated. For a 30cm ID pipe 1.5 meters tall, the total weight of media is about 260 kg (oof). The inside has a bottom surface of 700 cm2, and a total surface area of 15,000 cm2. That’s still only around 5 psi for a system capable of filtering 14 liters per hour.

Though 260 kg might be more than my apartment floor is designed for…

An 8" system would only weigh 80kg. Much more doable.

Maybe it would be easier to use plastic sheet and wrap it around a form. Or a round trash can. Or waterproof a concrete forming tube. Or use multiple 6" pipes in series. Or 55 gallon plastic barrels.

Biochar might be worth a look. It would certainly weigh less.

The actual filter depth only needs to be 50-60cm. The extra space is taken up by support materials and water head.

17 Jan 2022

If I was to try and invent the worst data storage format, I would arrive at bibtex.

There are special keywords that aren’t always keywords.

Keywords are capitalization insensitive.

Indentation is not standardized.

Escape characters are not exclusive, not always used (even in the same document), nor escaped themselves.

Comments are not standardized nor are they escaped in any manner.

There are nested braces and quote marks without escaping.

There are built-in text substitutions and markups (html, latex) which may or may not actually need to be acted upon and with no guarantee that html tags will be closed.

IDs are not standard and can contain any unicode character.

There are different implementations that can all be considered “bibtex”.

Basically, Bibtex is a context-free grammar’s worst nightmare.

27 Dec 2021

Ya know the 2001 Jimmy Neutron movie? There is a scene in that movie where Jimmy Neutron enters his lab and checks on all of his science experiments one-by-one.

Ten year old me thought that that was so cool. I still think it is awesome.

Each day I wake up, I have a morning routine of checking experiments. I turn on all the grow lights that aren’t on timers (3 of them right now). I also check the kratom to see if the nasty-terrible-no-good mealybugs have returned. I also do a general sweep of the plants’ health, growth of new leaves, color, etc., and then I spray them down like a morning spritz of the rainforest.

Then I check on the various seeds in each of my two germination chambers. Add water as necessary. Photograph if anything has changed. For the last couple days I have also been adjusting the N. nucifera timelapse as needed.

Then I check on the mushrooms in the fruiting chamber. Pick and mushrooms that are ready. Spray down the area and top of the humidifier reservoir if necessary. Right now I have several jars of pearl oyster that are fruiting (they are super delicious). If I notice any issues (e.g., lack of humidity) I check on the Mycodo controller to see if anything needs to be fixed. I also check on any jars of grain spawn that I have growing in the closet. Some need shaking.

I often have things in the dehydrator (e.g. beef jerky) that need flipping or whatever.

Just a lot of cool experiments at once. I think ten year old me would be proud.

22 Dec 2021

I set up the N. nucifera timelapse last night and started recording today.

To convert raw files to jpeg.

find . -type f \( -iname "*.raw" -o -iname "*.nef" \) -exec sh -c 'darktable-cli {} ${0%.*}.jpg' {} \;

21 Dec 2021

Made a DSLR camera controller out of the new Raspberry Pi Zero W2. This thing is so much faster than the W1.

I did the usual setup tweaks for the Pi W. Then I installed gphoto2 using the nice script from https://github.com/gonzalo/gphoto2-updater.

wget https://raw.githubusercontent.com/gonzalo/gphoto2-updater/master/gphoto2-updater.sh && chmod +x gphoto2-updater.sh && sudo ./gphoto2-updater.sh

I tried a simple php server but it didn’t give the control I wanted. I ended up just controlling via ssh command line.

14 Dec 2021

EBNF: It like regex but with recursion!

I have been exploring ANTLR which uses a modified EBNF syntax. I am trying to build a grammar for bibtex and it really sucks. There are so many variation and exceptions in bibtex that building a grammar is next to impossible. The keywords are mutable. The special characters can be used as nonspecial characters without escaping.

24 Nov 2021

Got the ElectricVeg site up and running. Very similar to this site.

\\textbf{(.*?)}

<b>$1</b>

\\par

<br>

\(\\href{zotero://open-pdf/library/items/.*?page=[0-9]*}{p. ([0-9]+-*[0-9]*)}\)

pg. $1

\\begin{quotation}\n\n<br>

<blockquote>

\\end{quotation}

</blockquote>23 Nov 2021

Zotero is a fricken mess. I mean, seriously. It’s just a front end to a database, some web scraping, and some text processing. Why are some of the files 40k lines long?! Why does a plugin have a database with three entries, one of which is over two million characters?! WTH?!

\[@([A-a]*[0-9]*), @([A-a]*[0-9]*)\]

% cite $1 $2 %

\[@([A-a]*[0-9]*)\]

% cite $1 %

\[@([A-a]*-[A-a]*[0-9]*)\]I tried for 6 hours today to add just four characters to the better-biblatex quick copy feature. I still haven’t gotten it to work. Seriously. Just adding the liquid tags to the quick copy citekey feature was impossible. I gave up after 4 hours of searching.

Ugh. I can’t even write the liquid tags.

20 Nov 2021

Art is weird. I use art generally to encompass most human endeavors including those with all except the most specific utilitarian function.

I think one of the reasons I avoid sports is because it is somewhat of a praise of handicapping. This is going to take some explaining… Also, this is a description, not a prescription.

For example, if the stated outcome of boxing is to determine the best fighter, they are doing it wrong. Boxing uses padded gloves to avoid the worst outcomes of fighting. I know, I know there are ethical reasons for that, but my point is that they are specific handicaps antithetical to the outcome. Every sports rule is an additional handicap that divorces the sport further from the real world.

Boxing is not attempting to find the best fighter. It is attempting to find the best fighter subject to all of the caveats and constraints of the sport. Why then do we tolerate and even praise these negative handicaps? Is it because it requires more precise skill with these rules, thus making it more exclusive?

And I know that that is part of the entertainment: no one watches soldiers killing each other on the battlefield for fun. Similarly people watch situational comedy because it is similar to real life but highly manipulated and controlled to be more palatable.

I was watching the latest Technology Connections video on a digital piano. He made a comment about the strangeness of digital pianos producing the prerecorded sound of a “real” piano and playing it back on some speakers. A cheap model like this won’t produce the same sound as a regular stringed version. Even if you could produce an electronic version that reproduces the original sound in perfect fidelity, most people would still have a preference for the original. That phenomenon is well known and not what I am talking about.

What I am specifically talking about is the preference for human hardship. Hand-crafted wood furniture sells at a much higher price compared to machine made, even if the machine made version is superior in every single objective quality.

A piano concert that had a “player piano” instead of a person performing would sell zero tickets even if the player piano was superior in reproducing the sheet music. Or, if you object to the idea that sheet music is the platonic ideal, reproduces the exact interpretive performance of a pianist from a prior engagement.

Perhaps this is a form of rarity preference. Each hand-crafted item or musical performance is unique. Rarity preference itself is weird since there are many reasons to avoid something unique, especially in utilitarian objects. A completely unique car would be next to impossible to repair since replacement parts are nonexistent.

But also a piano concert where the pianist surprise douses the audience in urine and feces would be completely unique. I’d wager that no one would attend the second showing, however. So the value isn’t purely rarity or uniqueness based.

Again, this isn’t really my point. My point is that excessive praise is given to people who accomplish something in lieu of some hardship. If that hardship was removed, however, the task would be easy. The end result is the same. Why should the fact that one set of circumstances elicited more work than another if the outcome is the same?

This is not to say we shouldn’t attempt to lift people out of hardship. I am fully supportive of something like “hardship grants” for people (especially students) who, by no fault of their own, experience negative environmental factors.

Directionality is important. What if the situation were reversed and those with less hardship were handicapped in some way to average them out among the population? No one would praise the most handicapped for their work despite the circumstances. Even if the magnitude of the handicap is the same as in the positive manner. Harrison Bergeron might have something to say about this “negative handicapping”.

If everyone is handicapped equally, no one notices. E.g. game shows with oiled rotating beams and inclines are quite popular. The rules of sports apply to everyone. Excluding the instances of cheating, of course.

So it is only in positively equalizing handicaps that we deem praiseworthy. Even if those handicaps are self-enforced, e.g. Youtube videos of “I built a wind turbine out of trash.” receiving millions of views when a massively more efficient turbine can be bought and erected in a few hours. We find amazement and heap praise on accomplishing things under stress or hardship.

Perhaps the value is not in the end product at all. Then again, a child might produce an finger painting that is cherished for a lifetime by the child’s mother but a random stranger wouldn’t pay to own it.

18 Nov 2021

Passiflora incarnata. Yep.

15 Nov 2021

Phew! The first ElectricVeg youtube video is up.

I think I want to grow a Nicotiana alata. I considered N. rustica because it is sufficiently popular but not mainstream or illegal.

However, I came across something that peaked my interest:

Flowers of N. alata emitted more than twice as much fragrance as any other species, particularly at night, and related species in section Alatae also were strongly scented.(Raguso et al. 2003)

N. alata fragrance is literally off the chart.

I might also do some general methods videos. But those have to be very well polished. I don’t want hacked together how-to videos that are only applicable to me.

I want to do a video on kava (Piper methysticum) but I can’t find any online sellers. Perhaps this is because they are difficult to grow? They definitely can’t be sexually propagated.

Kratom is another plant that deserves attention. Kratom, kava, and kanna haha

Then there is all of the cacti.

09 Nov 2021

And again… I somehow screwed up google analytics.

08 Nov 2021

Recorded all of the coffee germination script. I will definitely change things next time, but I think it is a decent first test.

My number on problem, as usual, is space. In order to adequately blur the background for decent separation, I was forced to sit within arms reach of the camera. This mean that even for my small S9 screen, you could see my eyes moving back and forth as I read which jars the audience out of the illusion of conversation. A different lens might work if I can’t find an alternative filming location.

Also, filming at my desk completely negates any alternative work I might want to get done concurrently. My entire day is devoted to filming and nothing else–made all the more difficult when I lose my voice after an hour of recording. I don’t really talk all that much day-to-day so even an hour of talking is sufficient.

At least my desk and fume hood are immaculate for a few days.

I learned a lot of blender video and audacity sound editing.

The M. speciosa trees are not doing as well as I had hoped. They have lost a lot of leaves, except the bumblebee oddly enough. That one is as verdant as ever. So much so that I included it as a backdrop in my video. The root system is beautiful.

The transition to their new home was probably a bit of a shock. All the worse because I didn’t fill their reservoirs as high as necessary. I noticed drooping leaves the next day so I quickly filled them.

I need a better air pump and a better way to measure air distribution.

03 Nov 2021

Lots of work.

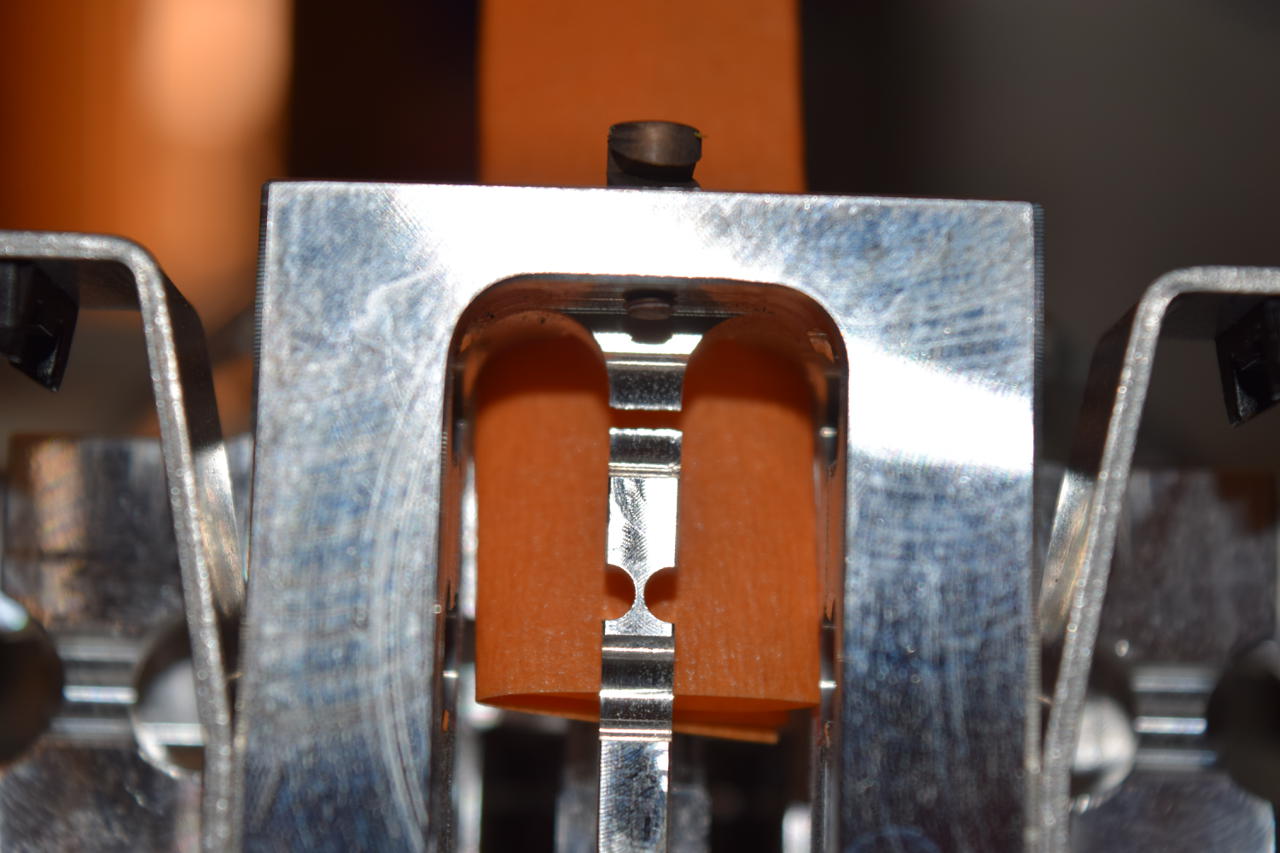

I built a teleprompter:

beam splitter glass

3D printed teleprompter structure

I am waiting on an OTG connector for my phone so that I can control the teleprompter app on my phone more easily. A larger screen would be better, but this will do for now.

Today I tested various setups for the first ElectricVeg video on coffee germination. I don’t have a lot of space for a decent depth. Oh well.

Oh I also wrote, rewrote, and rewrote again a script for coffee germination. The culmination of about three weeks worth of research (~150 papers read and annotated). I think I have something worth putting into a video now. I really hope this works out because I am running out of options.

I started a new batch of oyster mushrooms a few weeks ago. They really took off. I spawned some corn cob and sawdust substrate today. We will see how that goes.

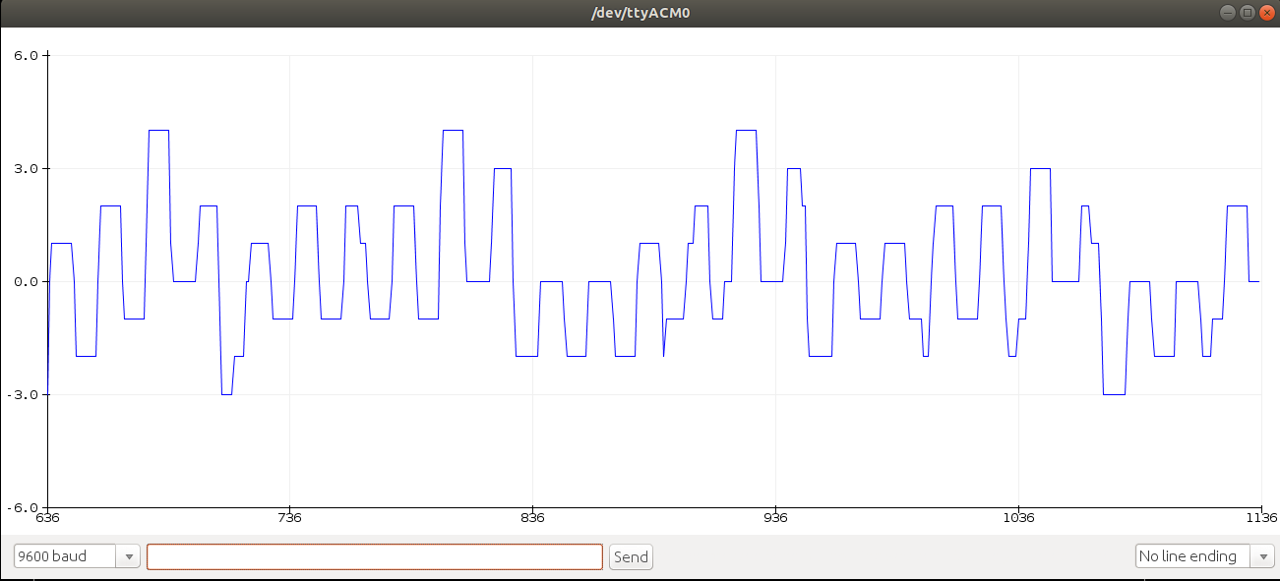

I built a germination chamber. Well… most of one. I’m still working on the controller. Trying to overengineer it, as usual.

01 Nov 2021

Moved the M. speciosa trees out of the closet and into the living room.

They have been growing like crazy in my closet for the last four months or so. They long outgrew the size of my closet width-wise, but have in the last week or so almost touched the grow lights. So it was time for them to move out. Actually, it was the time several weeks ago, but I’ve been putting it off.

Many of the larger branches are significantly curved or bent from the confinement. The lower branches had almost no leaves. I suspect that this is because of the single top-down light source. The apical leaf buds were still intact, just not growing. I am hopeful that they will sprout new leaves in the next few weeks now that they have adequate room and a little sideways illumination.

- 6.4g Masterblend

3.2g magnesium sulfate heptahydrate

6.4g calcium ammonium nitrate

10L water

26 Sep 2021

I didn’t sleep at all last night. So I decided to continue my research into building an analytical balance… as one does when sleep deprived.

19 Sep 2021

Full nutrient solution change on bumblebee kratom.

15 Sep 2021

Do normal people work 14 hours days for the fun of it?

11 Sep 2021

Sanded and painted. Painted and sanded. My fingers hurt.

10 Sep 2021

Designed some hash beads and pendants. 18 minutes, 4.4m to print, each, in sets of 9.

06 Sep 2021

More website work. There are probably more broken images. Finally fixed the custom css problems. Stupid bootstrap. I could customize the website css locally, but when I pushed it to the host, css would break.

Also, unlike the original markdown, pandoc markdown treats the ![alt]() alt text as a caption. I like that more, I just wish I would have known before I converted every image link on this site to .

I apologize to anyone who tries to use my website on a slow internet connection.

05 Sep 2021

Finally spent some time on the website. Fixed the carousel and reworked the images to match. Fixed the broken links. It still isn’t perfect, but much better than before.

03 Sep 2021

Furious work on the scooter project has ceased. Working at a much more leisurely pace now. I’ve been using so many rattle cans that my dominant index finger is numb and tingly.

I need to buy replacement bolts. I’ll pay extra for 316 stainless steel socket cap bolts. Phillips is stupid and should be outlawed.

Also, the pull toward a BOM website is definitely real. The struggle to understand, match, purchase, etc. parts for diy projects is substantial and duplicated every time a project is built. There must be a better way. Voron sourcing guide.

Finally bought an analytical balance. Mettler-Toledo AE200s: An ancient and bulky 0.1mg/205g balance. Not too bad for $160. I paid a bit extra for a guaranteed working item (with free returns).

Made my first Etsy sale.

There was a resurgence of mealybugs on the Kratom. On a completely different plant than before. I used an isopropyl alcohol soaked cotton swab to kill any that I could find. Then I spray down all of the plants with Eight permethrin.

Permethrins don’t seem to be very effective any more. There is probably some resistance going on.

I ordered an acetamiprid-based systemic pesticide. Hopefully this will control them.

Apparently resistance is easily gained after only a few generations. So the key would be to hit them hard and early. 1 2 3

Alternatively, lady bugs (Coleoptera) are predators of mealybugs, especially larvae. 4 If I continue to have and when the acetamiprid has sufficiently dispersed, I will try this.

As a last resort, I can use modified atmosphere treatment. However, the last time I tried this I let it go too long and killed my plant.

Given the neonicotinoid mode of action, suffocation in a modified atmosphere would probably happen faster if the two were used in combination.

Dry ice still isn’t available at my local Hyvee, at least, according to their website. I can order it online with a ridiculous shipping fee. I’ll have to check with Praxair.

In any case, they are almost too big for my closet now. I need a new space.

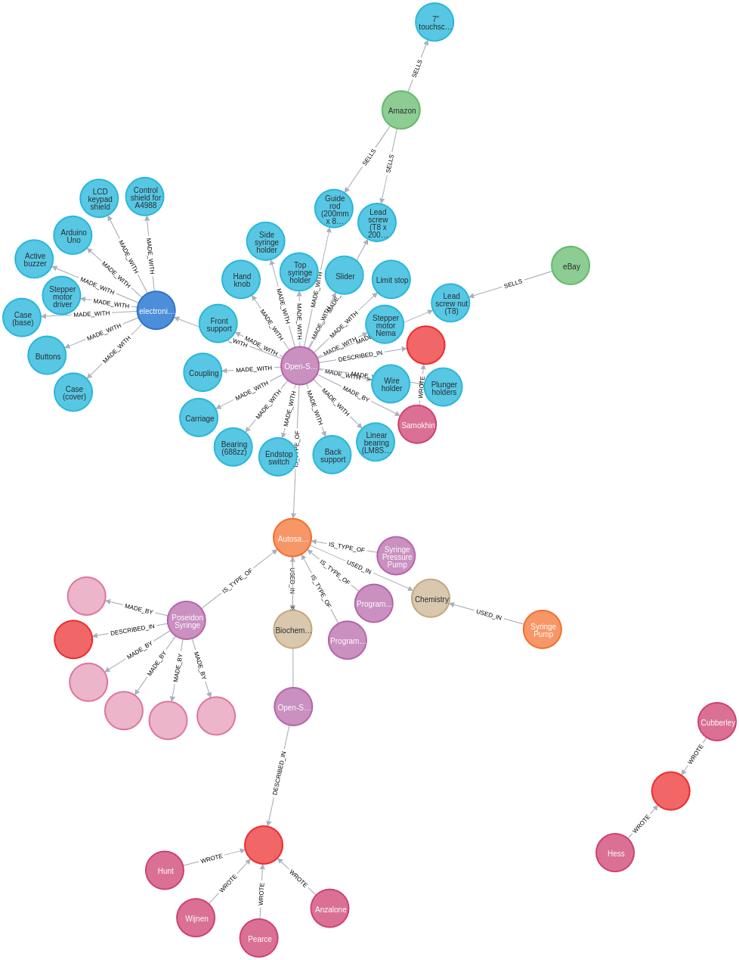

Ontology generation really shows you just how terrible our minds are. For example, when reorganizing ontologies, it is often necessary to abstract a certain feature but that extraction of said feature is near impossible. The color of a red balloon can be easily visualized differently and therefore abstracted, but the elasticity of a balloon cannot be unless you already know that mylar ballons exist.

Perhaps more illustratively, I am trying to abstract and objects intended use from its construction. A pulley is used to transmit linear motion of a belt to rotary motion, but that is merely a product of its construction, namely rotational symmetry. Sealing washers and plain washers have identical construction, but their deformation properties lead to different uses. So if I have an ontology based upon use-cases, switching to a property-based ontology is not trivial.

18 Aug 2021

Well that sucked. Aqueous ammonia generator was supposed to yield 1L at 30%. Instead I got 750ml at 7%. I’m sure a lot of it is still dissolved in the ~2.5 liters of reaction mixture. The reaction took 2 days, so I’m not going to run it any longer.

17 Aug 2021

A thorough guide to simple lithium ion charging circuits.

15 Aug 2021

Friction welded some bits of the scooter front fender. It must be made of polyethylene because of the trouble I had. Polypropylene would have been better.

I also reupholstered the seat. It will probably need to be redone. The material isn’t exactly upholstery grade.

14 Aug 2021

The ferric salt process uses a solution of ferric ammonium (or alkali-metal) oxalate. Typically, a 2% solution of ferric ammonium oxalate is used at 40°C, and the anodized metal is immersed in this for 15 min, the pH being adjusted to between 4·5 and 6 with oxalic acid or ammonia as necessary. For bronze colours the anodized material may be dipped successively in 2% cobalt acetate solution and then 2% potassium permanganate, at 35°C. (Giles 1979)

It can be seen that the ferrioxalate solution is liable to exercise an appreciable solvent effect on the anodic film at pH values below 4·5. Moreover, the colour imparted to the anodic film became more marked the higher the pH. Values between 4·5 and 6·0 appeared to be generally satisfactory. For accurate colour matching, it is essential that the pH be adjusted with oxalic acid from batch to batch. It was found that approximately 1 gm of anodic film raised the pH of 11. of 2% wt/vol ferrioxalate solution approximately 0·2 from a commencing pH of 5·7.(Kape and Mills 1957)

Some long term studies of inorganic dyes.(Kape and Mills 1981)

It seems that iron oxide based dyes (decomposition product of iron ammonium oxalate?) have excellent stability. Beyond that of any organic dye tested.

However, the gold colour produced by immersing the anodized metal into an aqueous solution of ammonium or sodium ferrioxalate was well known, and the colour seemed relatively stable as judged by some five years’ outdoor exposure in various places around the world.

A student’s lab procedure (Donahue and Exline 2014).

10 Aug 2021

09 Aug 2021

After weeks of CAD work, the Fungi Controller box v 1.0 has been printed.

05 Aug 2021

Did some scooter work.

5ml of orange oil and the same of dish soap works well as an ultrasonic bath solvent.

Every time I upgrade this computer, I regret not making a list of the changes I make and programs I install. Ahhh well. Maybe next time.

29 Jul 2021

Researched aluminum anodizing. I think I might have trouble with the scooter parts I wish to anodize. They are almost certainly cast aluminum which often contains significant amount of (unanodizable) silicon. This results in uneven coloration especially when a caustic preetching step is used.

I forsee two options: a preetching step that includes hydrofluoric acid or some other form of coloration.

I might have more luck with physical coloring.(Sheasby, Short, and Gupta 1981)

Or perhaps inorganic dyes would work?

28 Jul 2021

Finally found a proper vin decoding.

My scooter is a 1981 Suzuki FS50X.

My drive was throwing random errors and failed the SMART tests, so I bought a new solid state drive. Just a 480Gb Microcenter house-brand. It took all yesterday and most of today to install Ubuntu 20.04 and transfer my files.

I had some ethernet trouble on the laptop. Ethernet takes a long time to connect, if it connects at all. I installed a different driver sudo apt install r8168-dkms and rebooted.

https://askubuntu.com/questions/1308793/realtek-r8169-driver-ubuntu-20-04-with-rtl8111-8168-8411-pci-express-gigabit-et

https://jaredreisinger.com/blog/realtek-8111e-8168-driver-ubuntu/

edit I should have just checked the cable first. I found my roommate’s bike helmet stashed in the basket where I keep the internet router and modem. It had knocked the ethernet cable loose.

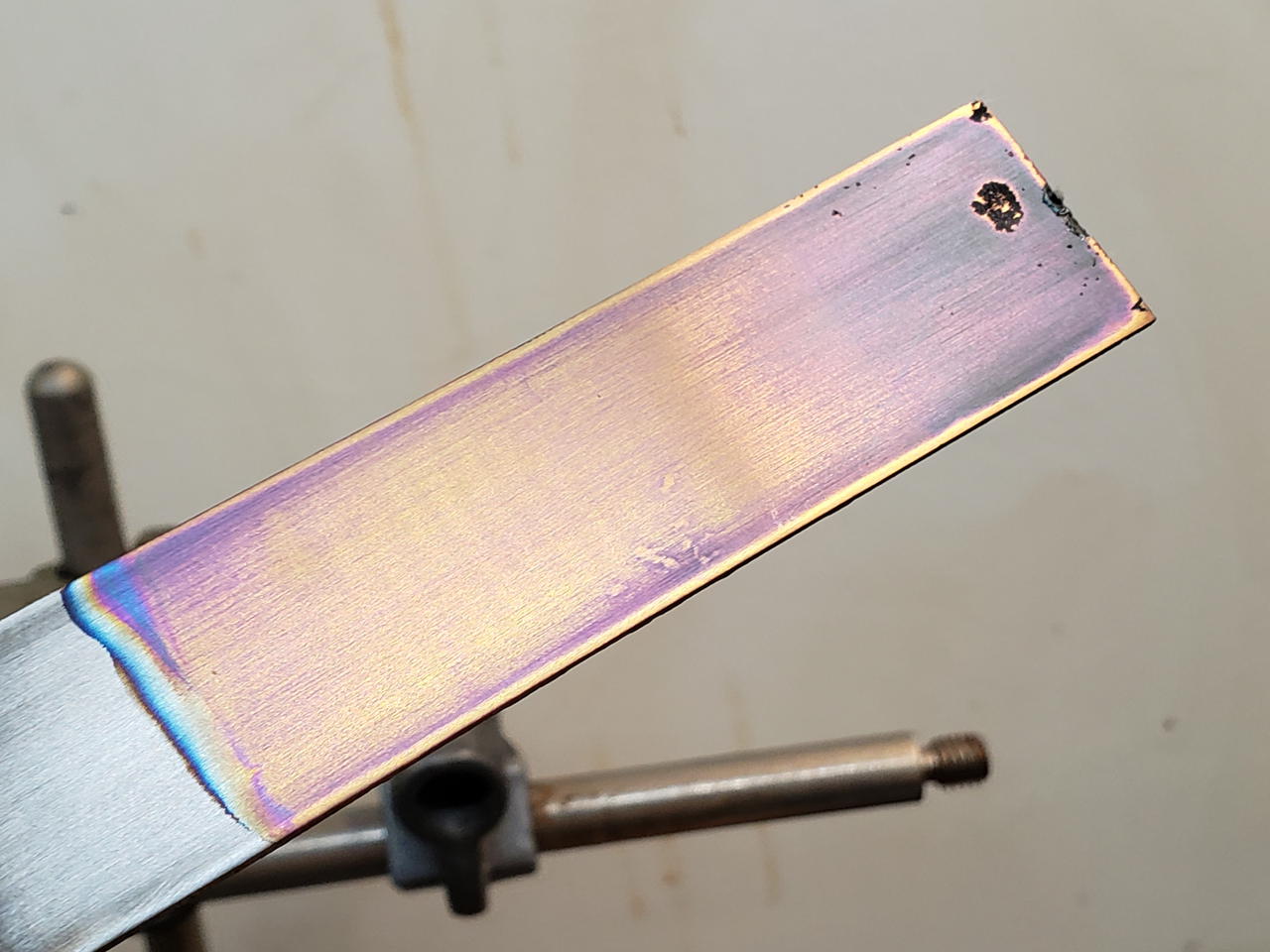

Did some titanium anodizing. At least until I burned a fuse on the variac by touching the two electrodes together at 35V.

26 Jul 2021

I bought a scooter last night from a friend. 1981 Suzuki FS50. It shouldn’t take much work to get it running again.

23 Jul 2021

The filament iglidurr page doesn’t exist.

I think it would be possible to 3d print the bearing out of PLA and then impregnate the contact surface with solid lubricant (teflon, graphite, molybdenum).

20 Jul 2021

It is so hard to find connectors without a name.

For the record, the connectors used on hot-swappable server power supplies are called edgeboard connectors:

| attribute | value |

|---|---|

| positions | 64 |

| positions per row | 32 |

| rows | 2 |

| pitch | 2.54mm/0.100“ |

| card thickness | 1.57mm/0.062“(1/16”) |

16 Jul 2021

Started printing the parts for a Precise peristaltic pump.

13 Jul 2021

The planetary mill research continues.

The more that I play with the numbers, the more that I think plastic friction wheels are fine. I don’t need 1 hp for 2x250g jars. I think scaling to 1/4 hp motor at 600rpm is more appropriate.

From the equations mentioned earlier, that means the friction wheels need a radius of at least 20mm and a contact thickness of at least 8mm.

I kind of just want to print a few gears and see if it destroys itself.

How to Design and 3D print basic spur gears (video playlist)

Or I could read a book/(Schultz 2004)

Engineering Principles for Plastic Gears

A pair of herringbone idler gears straddling the drive and planet gears might help distribute the load even more. The shaft of one of the idler gears could be pulled toward the other by spring tension to give a little play and allow for installation meshing.

I need to narrow down some design constraints. DC brushed electric motors are commonly available in the sub-1KW range with relatively low rpms for less than $100. They are intended for ebikes and such. Higher power means more cooling and more robust gearing, so it is best to think small.

| constraint | value |

|---|---|

| input power | < 500W |

| capacity | 2 x 100g |

| volume | 2 x 250ml |

| speed ratio | -2:1 |

Speed ratio is variable:

On the basis of video camera images, no considerable influence of speed ratio on the grinding ball motion pattern could be observed in the range −3bkb−1.(Rosenkranz, Breitung-Faes, and Kwade 2011)

Planetary mills get hot:

Temperatures over 200°C are typical in planetary mills operating at similar milling intensities.(Takacs and McHenry 2006)

This is unacceptable for pyrotechnic compositions (the impetus for this project).

12 Jul 2021

More work on the whistles. The spray mask worked well.

Retsch PM100 planetary ball mill parameters:

| feature | |

|---|---|

| base plate speed | 100-650 rpm |

| effective base plate diameter | 141 mm |

| max feed volume | 1x220 ml |

| speed ratio | 1:-2 |

| g-force | 33.3 |

| drive power | 750 W |

| material feed size | < 10mm |

| final fineness | <1 um |

33g’s is a lot for plastic to handle. I think with the forces involves, metal gears are necessary for the planetary ball mill. Certainly the shafts and bearings will need to be metal.

Alternatively, the eccentric ball mill design also looks interesting. From the video it appears that overheating is a major issue.

The greatest challenge when developing a high energy ball mill is keeping the temperature under control as the enormous size reduction energy leads to considerable heat built-up inside the grinding jar. product page

I think the cooling issue is too much to design for my purposes. Planetary mills are already complicated enough.

I have no intuition on the actual strength limits of plastic gears.

Friction rollers are an alternative.(Camargo et al. 2019; J. Lovo, Fortulan, and Leite de Camargo 2017) They are quieter than gears and are more reliable in the intense vibration of a mill.

I could not directly replicate the calculation of maximum rolling pressure for the friction wheels. The values given in the paper were different by an order of magnitude from the values given by the formulas. Considering that their machine has actually been built and isn’t quickly destroying itself, I’m inclined to think that the values in the paper are correct.

I do not have the same excessive power requirements. I would be happy with a machine that does 100g batches.

11 Jul 2021

I have been working on whistles for a few days. The running group I am a part of sells season passes that usually come with a personalized trinket of some kind. I volunteered to 3D print some things since my printer is back online now.

Here is one of the whistles hot off the printer.

The print is based on the Steam Train Whistle.

Personalized Train Whistle (FreeCAD file)

I also designed a spray paint mask to help the letters pop a bit more.

Each print takes about 13g of PLA and 1.5 hrs to print without support and 20% infill. Cleanup is minimal now that I have everything tuned and tightened properly.

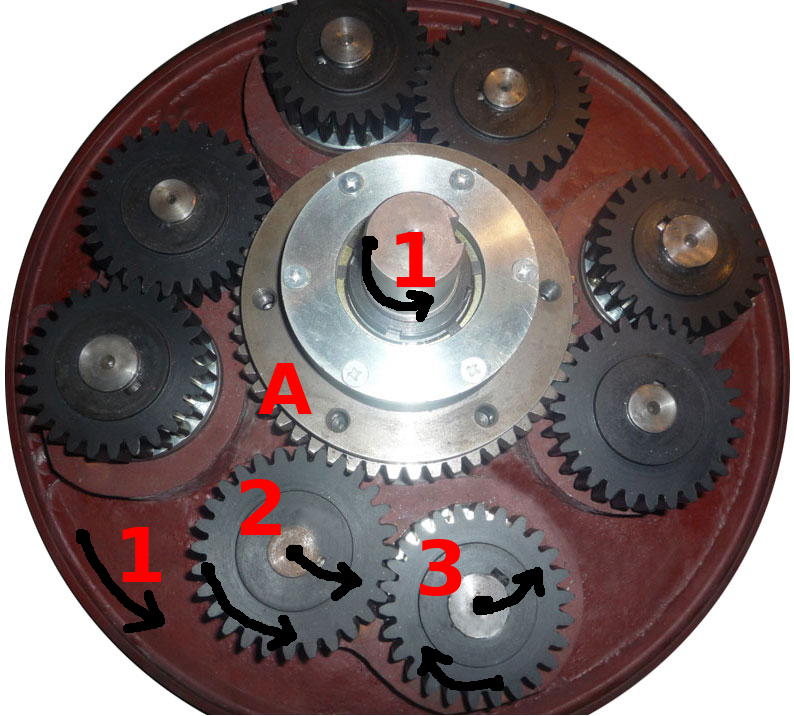

Plantary Ball Mill

I has taken me days to wrap my head around the inner workings of a plantary ball mill. Behold: the only image you need.

The is the view of the underside of the planetary ball mill mechanism. Image obtained from here.

The base plate (1), often called the “sun gear” counterintuitively, is attached to the central, keyed shaft that is driven by a motor. The immediate surrounding gear (A) is attached to the machine itself and is stationary. As the base plate rotates, it drags the middle gears (2) along the stationary gear, rotating them in the same direction. They, in turn, drive the final (planetary) gears (3) in the opposite direction. Gears 3 are attached to cages that surround your grinding bottles. The ratio between the diameters of gears A and 3 determine the rotational speed ratio (in this case it is 2:1).

An alternative explanation can be found here. (Camargo et al. 2019)

I must review the journal Machines at some point in the future.

02 Jul 2021

Open-cell polyether urethane foam is the type used in culture filter plugs. It is also used in packing, acoustic isolation, and outdoor furniture.

What do you do to a child who is misbehaving but also incapable of understanding (e.g. a baby crying at a wedding)? You distract them. You placate them, with lies if necessary. That is what I do to my mind when it doesn’t behave.

20 Jun 2021

I will fail by distraction.

29 Jun 2021

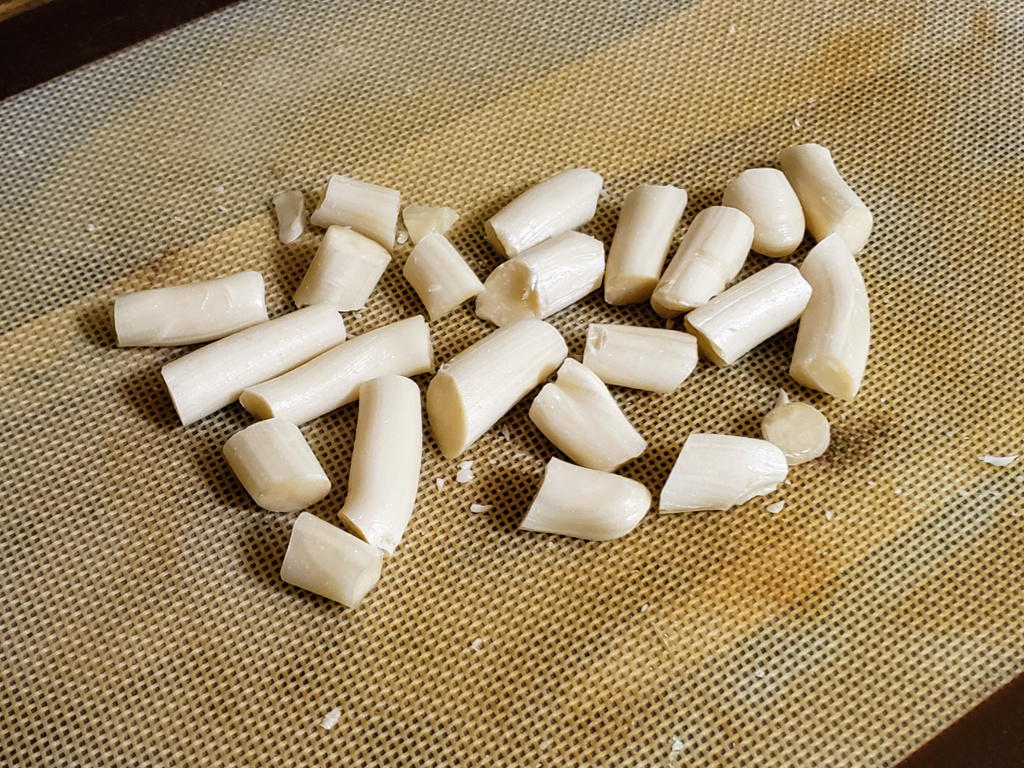

The zinc lozenges consisted of a boiled hard-candy base prepared with approximately equal proportions of sucrose and corn syrup, zinc gluconate trihydrate (AKZO Che-mie, Amersfoort, the Netherlands), a molar proportion of glycine (aminoacetic acid), and lemon and lime flavoring oils. The mixture was formed into lozenges that weighed 4.4g and contained 13.3 mg of zinc. (Mossad et al. 2996)

Zinc Cough Drops

Zinc gluconate is 14.3% zinc w/w. Corn syrup is 76% sugar. Honey is ~82% sugar. Soft-crack stage (~140C bp) is ~95% sugar. So for a 90g batch (18 5g drops) with 13.3mg zinc per drop:

- 50g sugar

- 40g corn syrup

- 10g honey

- 28g H2O

- boil to 140C

- 1.67g zinc gluconate (3.67 mmol)

- 0.28g glycine

- 1/4 tsp any flavoring oil (e.g. lemon)

Patients were given 120 lozenges and were asked to dissolve 1 lozenge in their mouths every 2 hours while awake for as long as they had cold symptoms.

It is probably best to keep lozenge intake below 120mg total zinc per day (half the batch or 9 lozenges).

27 Jun 2021

Storytelling is a dilution of pure reason at the expense of precision but the profit of applicability.

08 Jun 2021

That moment when you realize that there isn’t anything wrong with

02 Jun 2021

I’ve been through 21 pages of patent search results for peristaltic pump. I think I have a grasp of the design.

Integra Biosciences has some cool features. A “dispense” operation type where you specify the amount to dispense, a pause time, and a number of repetitions.

CDA USA Inc used a completely detachable cover.

The pulsatile flow of peristaltic pumps is at least somewhat derived from the partial collapse of the tubing under vacuum. After a roller looses contact on the outlet side, there is a momentary suck back caused by this deformation. The pulsation cannot be mitigated by altering the tubing collapse since that is a necessary consequence of the pumping cycle.

You could, however, solve this somewhat by allowing a small backward leakage after the opposing roller has sealed the tube.

This wouldn’t solve the issue completely. The tubing is also partially stretched by the friction of the rollers being pulled along by the tubing instead of mechanically driven by the motor.

Even if the rollers moved along their respective shafts with zero friction, some amount of friction between the tube and roller must exist in order to turn it.

Think of a staight tube with various roller designs: A non-rolling curved “foot”, a single roller, a dual roller, and a driven-dual roller.

This only works in principle for a straight roller. The difference in radii on a circular track means that there will always be some stretching.

Also, when a roller exits contact with the tube, the tube is free to retract to a position tangent the next roller and exit. This extra slack is incorporated into this patent. The rollers are also designed so that when one is losing contact, another is gaining contact.

Extra rollers are needed for the slack design since during the slack phase, one roller is not used to prevent back flow. Four rollers would be necessary for a quick release 240 degree design instead of three.

Larger rollers are better than smaller (more surface area applying force to the tube). Driven rollers are better than nondriven rollers.

How do we keep the roller engaged to the driver but not the tubing at the slack point?.. Separate tracks. That would also require a different head for each tubing size (less adaptable).

01 Jun 2021

Apparently there are a lot of peristaltic pump designs in the patent literature. Finger-type pumps look awesome but more complicated than I want.

I was originally looking for possible quick-load mechanisms. There are flip-top designs and bistable latching designs. And ones where the rotation of the rollers are perpendicular to the axis of rotation of the head.

There are some cool roller designs that might minimize the damage to the tubing. Also inverted pumps with the rollers on the outside of a stationary core.

With the control provided by a stepper motor, I think it would be possible to reduce the pulsation by slowing down the motor at the point where the roller separates from the tube. Or you could use cleverly designed housings.

I don’t know why, but all patents seem to indicate their pumps running counter-clockwise. Yet all of the pumps I have watched in operation run clockwise. It doesn’t really matter since they run in either direction, but it is just weird.

17 May 2021

Trying to get a Zebra printer to work on Ubuntu is ridiculous. Randomly it doesn’t print. The only error message you get is the single LED circle changes from green to amber. Libre office writer won’t accept custom print sizes. I get the whole thing set up and working ok, then Libre office decides to rotate to landscape without even giving me the option to change it. It’s fucked.

2 5/16 x 7 1/2 58.7 x 190.5

https://www.techrepublic.com/article/how-to-configure-a-print-server-with-ubuntu-server-cups-and-bonjour/

05 May 2021

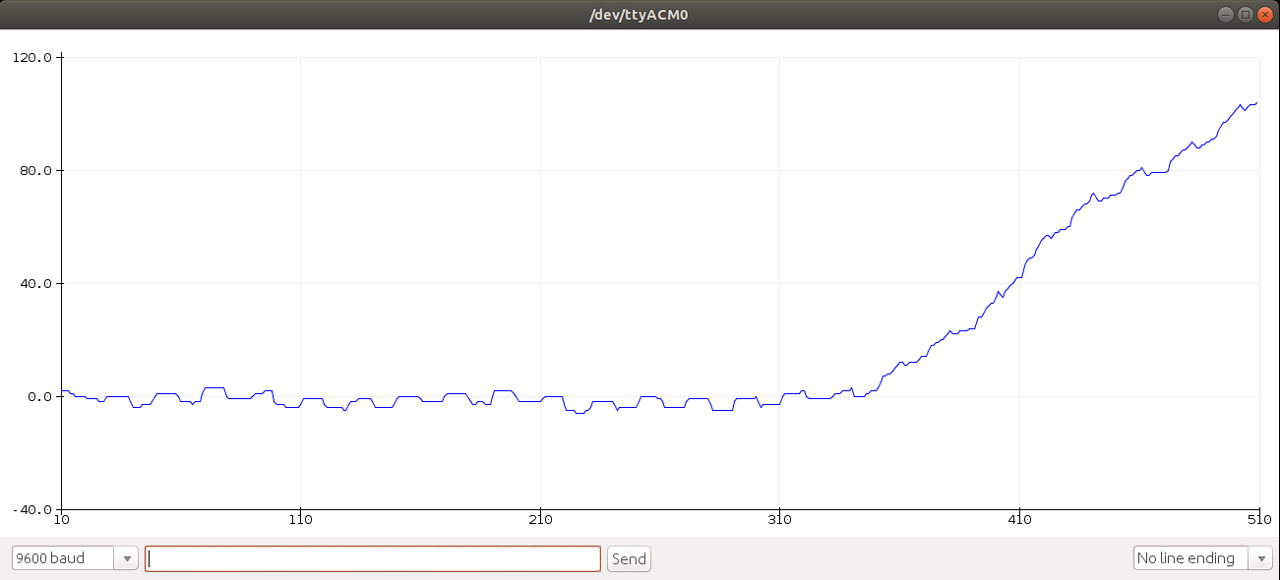

Initial testing of the incubator is going well. 5V across a single element raises the temperature surrounding the coil by 6 degrees C (18-24C).

04 May 2021

I finished the silicone application and applied a second layer to the rest of the incubator coils. Each nichrome length has a resistance of 6.4 ohms. The two can be connected in series or parallel.

03 May 2021

It has been a flurry of activity. Finished the HEPA flow hood mark II. It is quite heavy. Maybe 75 lbs. Enough that I reinforced my glass desk that it sits upon with three stilts. Right now, I have a separate stainless shelf piece that I set up in front of the flow hood to use as a table. Quite a janky setup, but I don’t really have room for it anywhere else.

I also started building an incubator for fermentation. The first thing I want to do is make some koji for miso. That required something like 30C fermentation temperatures. So I RTV siliconed some toaster nichrome wire to the bottom of a glass aquarium.

29 Apr 2021

Raspberry Pi Zero W, RPi Pico, Arduino with wifi board, RPi with usb wifi dongle, etc.

I’m going with Rpi Zero W for SiLA compatible laboratory equipment. It is python programmable. Wifi/Http/RPC compatible. Includes SD card interface for data storage. The pico is nice because it features built in analog pins, but that isn’t a deal breaker. If the pico didn’t require a $13 wifi board, I would probably go with it.

For some reason all the resellers are limited to 1 RPi W per customer. Rpi W also has hdmi and usb connectors for touchscreens (although cheap screens use GPIO).

27 Apr 2021

Struggling with the choice to pursue GAI or something more provincial. On the one hand I have the slim chance of success of developing GAI with the potential to help everyone on the planet. On the other, I have a (more likely) chance to develop a decent business that would be fun but definitely less helpful in the grand scheme. I may go the rest of my life and never succeed at GAI. I believe the business success is much more likely.

26 Apr 2021

Ebike

70 INR18650-35E cells: 14s 5p

Mid-drive vs. Hub motor: Mid drive

https://www.youtube.com/watch?v=8tAkU9HW6SY

Bafang BBS02B

Patents

CopyLeft; PatentLeft; Open; Gratis/Libre; Open Knowledge;

Imagine a cryptocurrecy tied to a patent system. New designs share value with old design proportional to their contribution.

I forsee a big problem: How do you calculate the diff? Even in the massive github, diffs are calculated by line. There is no representation of higher level conceptual differences.

Crypto like STEEM rely on manual curation with shared profits for curation.

If we are talking about 3D models, for example, everyone, at some point, used a simple cube. But you cannot patent a cube. Or perhaps you can, but so can anyone else. And if all of the cubes are the same, they split the reward. Then again, no one is going to download a primitive cube.

The STEEM whitepaper has some interesting points here.

An upvote system: every download, click, read, etc. contributes to a knowledge atom’s value. Downloads are worth more than hovers.

Patent trolls; sybil attacks; karma whore

Your upvote is compared to others’. If you are the only one to upvote an atom, while there are thousands of downvotes, you lose credibility/karma (value).

Trust circles: See if anyone you trust has moderated/curated/produced. If you countervote, all of the users who voted opposite to you are pushed out of your trust circle. This will isolate.

A metrics dashboard: Set your individual trust calculations. https://en.wikipedia.org/wiki/Trust_metric

Trust = global average + friend of a friend average + circle of trust average + credible source average + …

External sources are a problem. It is difficult to track external knowledge. Copying knowledge into the system runs the risk of copyright issues.

A learning community: Reading, practicing, learning are also good things but not necessarily valuable. Traditional education has a very long payout period: decades at least.

That level of interaction might be prohibitively data intensive.

Contribution should be free.

Tying money (or crypto) makes this an attractive target for nefarious parties. Maybe not the best solution.

Regardless, the real problem is diff. Solving this problem will also solve the general organization of knowledge problem.

10 Mar 2021

It is comforting and aggravating to know that I can spend a day at my whiteboard attempting to de novo determine the best methods to extract meaning from a collection of Python github repos only to find everything I figured out was in the Ontology Learning Wiki.

49.8g

07 Mar 2021

Who needs structure lead dioxide anodes when you can just throw a bunch of PbO2 powder in a pipe? (H Menon and Sadhik A 2015)

Pumping can be achieved using either a simple air-lift or pneumatic ejector pump.

03 Mar 2021

A powered rowing machine using a torque controlled motor would be cool.

02 Mar 2021

Thinking about SRS software. There’s an inherent problem with Anki and Mnemosyne (I haven’t tried other SRS software). Learning novel information and reviewing old info are antagonistic. Learning new information can easily be overtaxing and this is often the reason people don’t stick with SRS. With a pratically infinite amount of information to learn, some amount of restraint or ordering is necessary. Reviewing old info doesn’t have this problem: You review whatever is necessary for retention and the info gets spaced out with easy feedback from the user.

Take, for example, learning a new language. You must manually start by adding the simplest of new words to a SRS deck. You then learn those vocab word sufficiently before proceeding onto the next most complex topic. There is an order to knowledge. If, however, you simply added the whole of the language up-front, you would quickly develop a backlog of high complexity cards that you cannot possibly know or even comprehend.

Put simply, using “I don’t know the answer” as feedback in SRS is insufficient for (learning) ordered knowledge.

This is why sharing decks doesn’t work except in the simplest of topics.

Some users suggest that you only add cards that you have just learned manually–treating SRS simply as a rehearsal software. This skirts the issue by relying on the brain to order and categorize knowledge up-front. This works, but is not the ultimate goal of SRS. Or perhaps the more profound goal of SRS users which is to increase memory AND learning.

There are two solutions to this: a priori and a posteriori. The former being some sort of universal knowledge ontology. The latter being feedback from the user after info is presented. Likely the best solution will be to use some combination of a priori organization with a posteriori feedback.

Better still would be a system that works in conjunction with SRS to give the user knowledge that has yet to be (or may never be) committed to memory in a timely manner. E.g. adding references to a document while it is typed. But that’s more complex.

01 Mar 2021

It’s the mundane details of life that really get to me.

Yesterday I spend 5 minutes researching the difference between stannous and sodium fluoride while crouched in the Walmart toothpaste aisle. I learned that stannous fluoride, while being generally less tasty and with a propensity toward surface staining, is way better for teeth. Sodium fluoride is the bare minimum of oral care.

I’m not sure how many people know this but they certainly haven’t shared it with me directly. It’s not a distinction that I learned in school. The label probably had all of the information I needed, had I not been so desensitized toward hyperbolic advertising to neglect it entirely.

Given my lack of professional oral hygiene care lately, the switch to stannous could literally add years to my teeth-life. In vitro comparison of stannous fluoride, sodium fluoride, and sodium monofluorophosphate dentifrices in the prevention of enamel erosion

19 Feb 2021

I added a 3+ year old refrigerated packet of Lalvin ICV K1-V1116 to a tsp of sugar in 200ml of water yesterday and let it hydrate/grow for about 6 hours. Then I added half of the mix to the CO2 generator and let the rest sit with a paper towel gas exchange cover. The idea is to increase CO2 production but also to use up old yeast.

Also, pain is a nebulous thing. Pain can be weakened or intensified by thought. This morning I came to the realization that I had overinflated my air mattress and that that was causing serious sleep disturbances and pain.

For background, I sleep on an air mattress with a three inch thick latex memory foam pad on top. When the stars align properly, it’s the most comfortable bed I’ve ever slept on–Not that I’ve sampled a lot of high-end mattresses.

The air mattress that I currently use is the cheapest Wal-Mart has to offer. The kind with ribs. The manufacturer calls them “Dura-Beams” and advertises them as designed for comfort when, in fact, they internal connecting ribs are a necessary part of construction to keep the bed from becoming a perfect cylinder.

So those ribs for an uneven surface. A surface that is variable depending on the pressure in the bed. In the past, slow leaks have resulted in a deflated bed and terrible sleep. So in my mind I equated deflation with terrible sleep.

In response to that belief, this last refill of air (a few weeks ago) I decided to inflate the bed to its maximum. Ever since then I have had terrible sleep, but I didn’t even consider that the inflation could be the cause. I was trying to reason how my sleeping position was different or maybe how the increased CO2 from the ferment was the cause.

All this is to say that sometimes going back to first principles and reevaluating premises is important. All it took to return my mattress to its proper comfort was to reach over and let a little air out. Now I can sleep.

Well… not now. Now I’m awake and I have to work.

18 Feb 2021

CO2 concentration only reaches a peak of about 550ppm last night. I left the furnace blower on all night just to be safe.

Fermentation has slowed significantly but it is still bubbling away.

Harvested some Bacopa today. Mostly because it was getting out of control. 210g wet weight. It is drying now.

I learned all about zinc absorption and its inhibition of copper my findings.

I also started using Anki again. This time, however, I’m creating a reference database as well. It is for things that I have learned by don’t necessarily need to remember completely: just the reference. In the case of zinc/copper, all I have to remember is that my conclusion is in my reference db and look at it.

17 Feb 2021

Well I guess dry ice is out. I suspect that the vaccine distribution has consumed most of that. My CO2 generator mix would require 343g magnesium sulfate and 117g sodium bicarbonate. What about limestone and hydrochloric acid?

62 liters of CO2 requires 560ml concentrated hydrochloric acid and 280g calcium carbonate rock.

That’s kind of a lot, but not impossible.

I could also ferment a sugar wash. 300 ml of 280g/L sugar can be fermented with traditional baker’s yeast can generate about 5L CO2 over about 7 hours at a peak of 20ml/min. CO2 evolution continues at an ever decreasing rate. (Jerry, Mohammed, and Mohammed 2017) So a 1 gal wash would be sufficient. Hmmm… I like this idea.

Of course, the best source would be a CO2 cylinder. But who has that kind of money??

CO2 generator

For killing spider mites on a plant in a 66qt tote using a 7 liter sugar wash CO2 generator and hand warmers.

- 7 liters water (pinch of sodium metabisulfite to remove chloramine)

- 2 kg sugar

- 115g bakers yeast

- 4 hand warmers (~100g active iron)

Factors contributing to success

- slow release CO2 continuously

- I doubled the required starting materials

- LECA hydroponics allows for faster root air exchange than soil

- black plastic bag cover reduces photosynthetic oxygen production

Factors contributing to failure

- Not enough iron to absorb the released oxygen by the plant

- CO2 doesn’t penetrate deep enough into the root ball to kill everything

- spider mites may have some resistance to high CO2, possibly during diapause (Suzuki et al. 2015)

- leaks result in lower CO2 levels than required

- too little (or too much) water in the reservoir requires early termination

- yeast is too old to produce enough CO2 (should have used not 3 yr old yeast)

- room temperature (21C) is too low; mortality is inversely proportional to temp

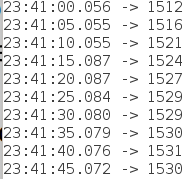

After 1 hour, the CO2 bubbles are coming about once a second. The hot packs are at about 40C.

After 2 hours I can smell the sweet pungent vapors of the fermentation.

It seems that diapause is induced at low temperatures in spider mites. The temperature depends on the particular species and some warm-climate mites have 90% diapause at 15C. (Takafuji, Tajima, and Amano 2007)

I’m going to turn my heater up to 24C for the duration of the experiment. edit: no I’m not, that’s uncomfortable

After 10 hours the CO2 concentration in my room has risen to above 1500ppm. That’s not great for the human and dog respirators who have to sleep in this room. I’m actually starting to get a mild headache.

16 Feb 2021

I am still having spider mite troubles. I’ve tried insecticidal soap, neem oil, and pyrethrins. I think it is time to seriously consider modified atmospheres.

Oxygen absorption is still an issue, however. Modified atmospheres work best with low oxygen, high carbon dioxide, and moderately high temperatures. My first attempt at a modified atmosphere used two “hot hands” oxidation based hand warmers to absorb oxygen. At the end of 48-hours, the sachets were definitely used up and there was probably still significant oxygen left in the now deflated trash bag. I neglected to consider the amount of oxygen that the plant was producing.

I think in the future it would be wise to keep the plant in the dark during the procedure. That way, the plant is releasing minimal amounts of CO2 and actually absorbing some of the oxygen.

Iron oxidation is only viable for small containers. I briefly considered turning my entire (~6 cubic meter) closet into a MA, but stopped after calculating that that would require around 4.2kg of iron.

A 66 quart tote would only require about 43 grams of iron. Assuming about 50% iron loading (source), that’s only two hand warmers.

I briefly considered using a propane flame for generating carbon dioxide as well as consuming oxygen. I am worried about CO, however. It seems that catalytic heaters do not have as much of a problem with CO.

When the catalytic heater was operated in a closed room (ACH ~ 0), the oxygen was depleted from an ambient concentration of 20.9 percent to 8.8 percent.

Catalytic heaters do suffer reduced efficiency at low oxygen concentrations leading to unreacted propane leaks. With regular propane burners, the flame would just go out.

As the oxygen decreased in the chamber, the catalytic heater became less effective at converting the propane and oxygen to carbon dioxide and water vapor. This was reflected by an increase in the hydrocarbon concentration in the chamber, which ranged from 1,050 ppm to 13,440 ppm (5 to 64 percent of the lower explosion limit of propane in air).

A random website suggests that a plant can produce 500ml oxygen per hour per square meter of leaf surface area. My P. auritum currently has around 0.2 square meters of leaf area giving about 100ml per hour. So if the plant was left to photosynthesize, I would need a least 5 grams of iron oxidized per day. That isn’t too bad.

So, it might be sufficient to toss in 3-4 hot packs and flood the chamber with CO2. I think I will buy some dry ice this time instead of fiddling with an epsom salt/sodium bicarbonate CO2 generator. Unfortunately, my CO2 detector only goes to 5%.

In other news, my 3d printer is down right now.

25 Jan 2021

Thermoacoustic cryocoolers might be a way for the amateur to build a vacuum cold trap. A typical 1L liquid nitrogen trap might need refilling once per day. That’s a heat input of approximately 8 watts. Even with a COP of 0.1 that’s easily achievable.

I wonder if you could 3D print a suitable cooler? The best heat exchangers seem to be made of mylar. What about printing the system and then chemically depositing silver?

Extensive calculations (Kakaç, Smirnov, and Avelino 2003)

20 Jan 2021

OOOOO… Arduino compatible stereo mems microphone sensor with a 69dBA SNR for ~$15 S2GO MEMSMIC IM69D.

19 Jan 2021

I filmed an intro video for my YT page. It’s all of about 3 minutes with a lot of pauses. I hate it. But I’m going to upload it.

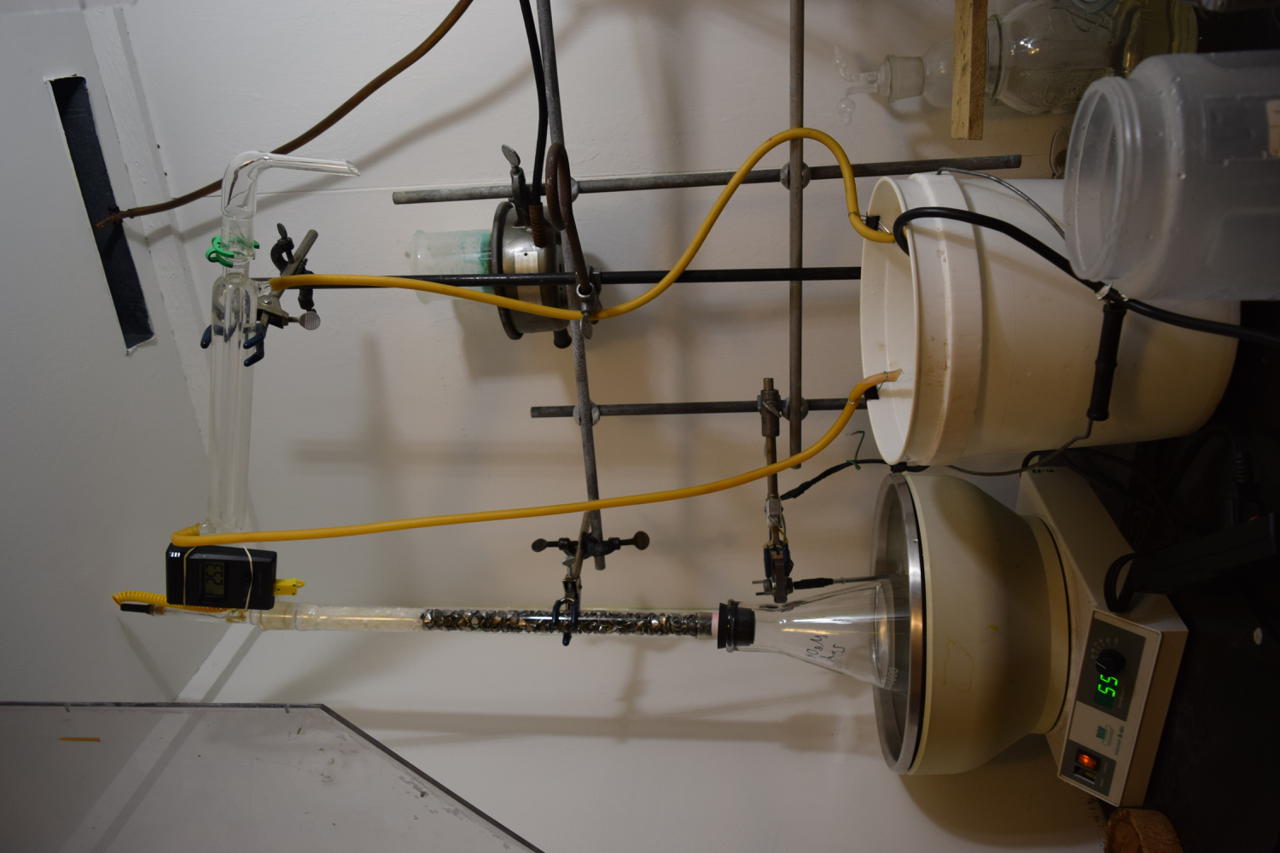

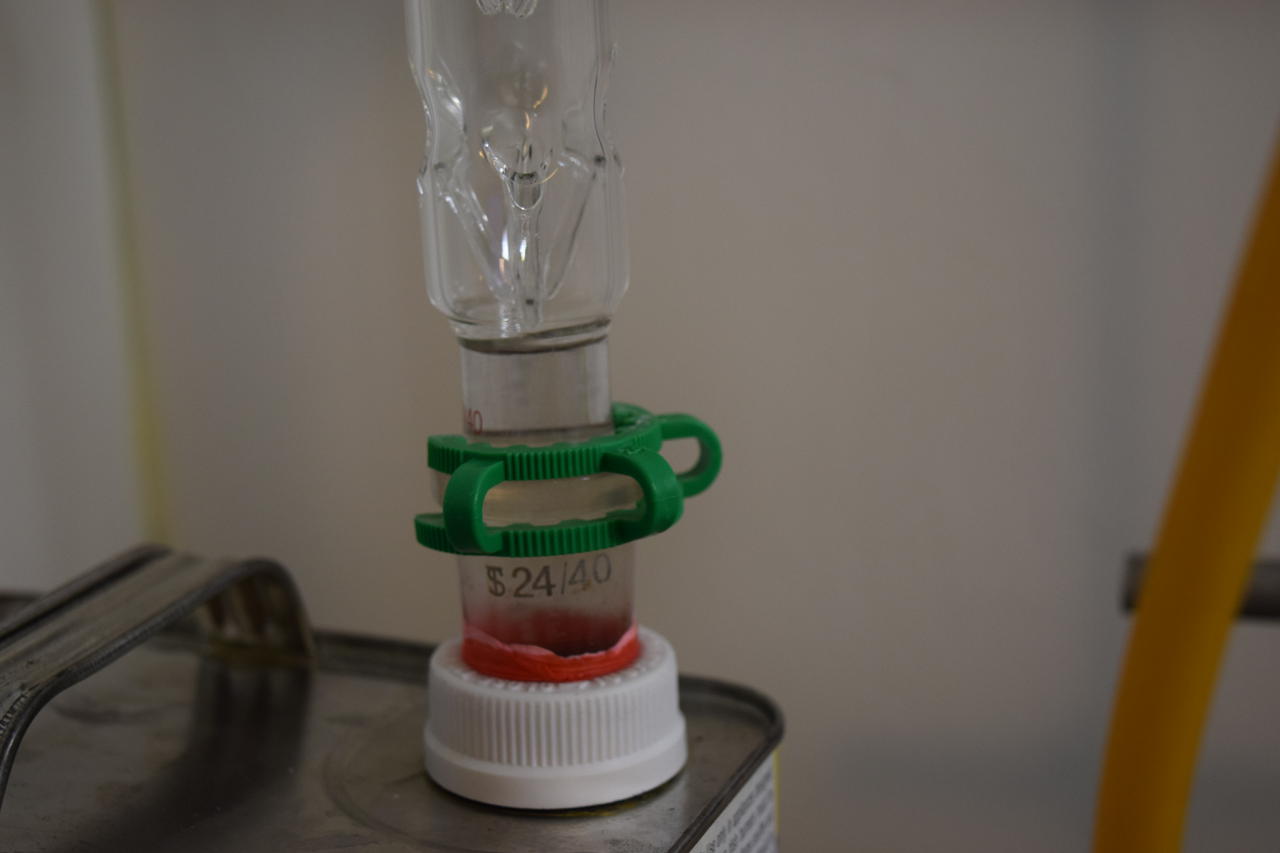

I finished the Buchi flange screw and uploaded it to Thingiverse. I found a vapor duct on eBay for relatively cheap. When it gets here in a few days I will (hopefully) have a working rotavap.

09 Jan 2021

I wonder if rotary progressive cavity pumps would be useful for HPLC? They would provide steady state flow with speed-proportional flow rates. Some commercial models designed for large flow applications are capable of 25-40 bar. Scaled down to HPLC sizes I bet that would reach many hundreds bar.

17 Dec 2020

The last two days has been a flurry of activity. Probably a rebound because I was so depressed in the week or two prior and getting nothing done.

But after crying in the shower once or twice, accepting my depression, and maybe some correlated/causative environmental changes, I have returned.

08 Dec 2020

Waiting on Amazon nowadays is a real PITA. I can’t continue my work on the syringe pump or the 3D printer because I am waiting on Amazon to ship a pair of crimpers. And before you think anything, I already checked my local stores for an appropriate pair and nothing.

01 Dec 2020

A how-to on combining neo4j with scikit-learn.

OpenCitations has a huge doi-to-doi citations database. They have dumps and a REST api.

Wikipedia list of citation indexers.

Zotero’s groups are all numbered https://www.zotero.org/groups/[XXXXX]. A script could try each number and detect whether a public group is accessible. The citations could be gathered that way.

ParsCit is an old program for parsing a bibliography into individual citations.

30 Nov 2020

I spent the entire day researching so I could save a few dollars at most.

Don’t get me wrong–I learned a lot along the way. I learned all about thermal sensing technologies and the differences between them. But ultimately this knowledge was being used to differentiate between a maybe $10 solution and a $5 solution.

I wonder if my time is wasted.

I wonder that a lot.

26 Nov 2020

It is crazy that imidacloprid is sold for literally 100x higher prices in the form of animal flea treatments than almost pure powder pesticide.

Theoretically, one could formulate their own flea drops by mixing 20 grams of Imidacloprid 75 WSB in a total volume of 100ml 99% isopropyl alcohol forming a suspension equivalent to 120mg/ml. Then each month, 1/2ml can be applied to each of your 8lb cats and 1ml to your 16lb dog to kill fleas.

That 100ml which costs $3.63 contains enough flea medicine for about 4 years. The carrier, isopropyl alcohol is safe for topical treatment of cats and dogs. Imidacloprid is safer than most flea treatments, with a wide therapeutic window.

Ya know… theoretically.

24 Nov 2020

I printed off a bunch of cable spools. The tidiness is amazing. I feel so much better (calmer?) when I am organized.

I’m looking into vapor polishing some 3D prints. I have an extra 5 liter vacuum chamber laying around. I haven’t used it for anything because it is lacking a gasket. So I am attempting to make one out of silicone caulking right now. I sprayed silicone spray lubricant with teflon on each half before applying caulking. Only time will tell whether I have just glued them together.

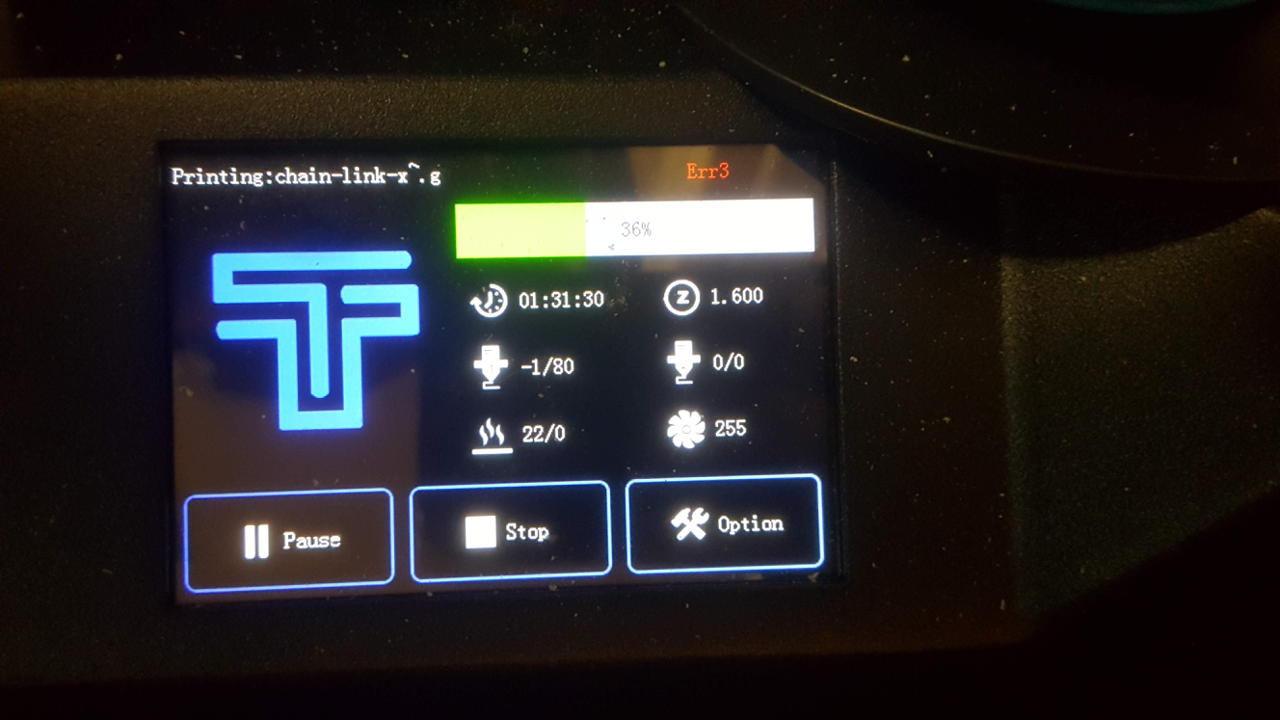

My 3D printer keeps throwing errors and stopping in the middle of a print. I finally noticed that the extrusion temperature readout was showing -1.

So I’m guessing the temperature probe is either disconnected or broken. Since I’ve been prepping for a linear rail rebuild, I’m going to replace the probe at the same time.

08 Nov 2020

Thinking about humidity and mushrooms…

I’ve been working on a humidifier: A tower evaporative humidifier where filtered intake air is passed counter-current to heated water. The water temperature can be adjusted to give humidity anywhere between the intake air dew point and saturated air above ambient.

But how to measure humidity? Typical, cheap capacitive sensors (e.g. DH22) lose accuracy quickly as you approach 100% relative humidity. They also have significant drift over their relatively short lifetime.

I see two (fun) options: psychrometry and chilled-mirror.

A chilled mirror hydrometer would be pretty cool. There’s already an attempt using arduino. However, chilled hydrometers suffer from the same lack of accuracy at 100% humidity.

Assuming perfect saturation, the air temperature that comes out of the humidifier is the wet-bulb temp. You could use the difference between the intake and outlet air temperature to determine the relative humidity. High accuracy temperature measurement would be necessary.

Looking at a psychrometer chart, if we assume the air intake to be 22C at 50% relative humidity then the wet bulb temperature should be around 15C. That’s only a spread of 7C.

Assuming linear conversion at full scale (just a ballpark estimation), a 0.1C temperature accuracy gives about 0.4% humidity accuracy. Similarly, a 0.5C accuracy gives 1.7% humidity accuracy. I think 0.5C is good enough.

The DS18B20(pdf datasheet) is a common temperature sensor with 0.5C accuracy. It is relatively cheap and does not require separate measurement circuitry.

It is possible to design a circuit based on op-amps and two RTDs to directly set the humidity. But I want to incorporate some timing and datalogging as well, so an arduino based design is what I’m going with.

07 Oct 2020

So some things happened.

Halloween trail went relatively well for the participants. For me and my crew, however, it was frantic and we failed in a few areas. I think the largest failure was that we forgot to bring water and I feel really bad about that.

An election happened. I served as a poll clerk for the second time. Of the 1600 registered voters in the two districts I served, about 250 people voted in-person. About twice that number voted by mail. So, ya, about 46%. Not great.

Plant things happened. My calendula started flowering. I finally examined my cacao trees to find that they were all dead. That’s super disappointing.

Mushroom things happened. A couple Lion’s Mane jars started fruiting through the 1/8th inch holes and two layers of felt filter material in the lids. Quite remarkable. So I’ve been scrambling to get the grain jars into fruiting media asap.

I made a batch of supplemented sawdust media: 5 lbs of 80% hardwood fuel pellets + 2 lbs wood chips + 5 oz gypsum + 1 lb 6 oz oat and wheat bran.

I’ve been 3D printing all the things. I bought a Two Trees Sapphire Pro linear rail 3D printer two weeks ago. It was easy to assemble and it started working without any issues. The included 200g of PLA filament was terrible. It would randomly break and ruin a print. Still… I was able to produce the winged hourglass tops for my and Erin’s plague doctor costumes.

One of the endstop switches failed on me yesterday. The actual mechanism failed. Not the connections, which is quite unusual. I need to tighten the belts; they seem to have loosened since installation.

29 Oct 2020

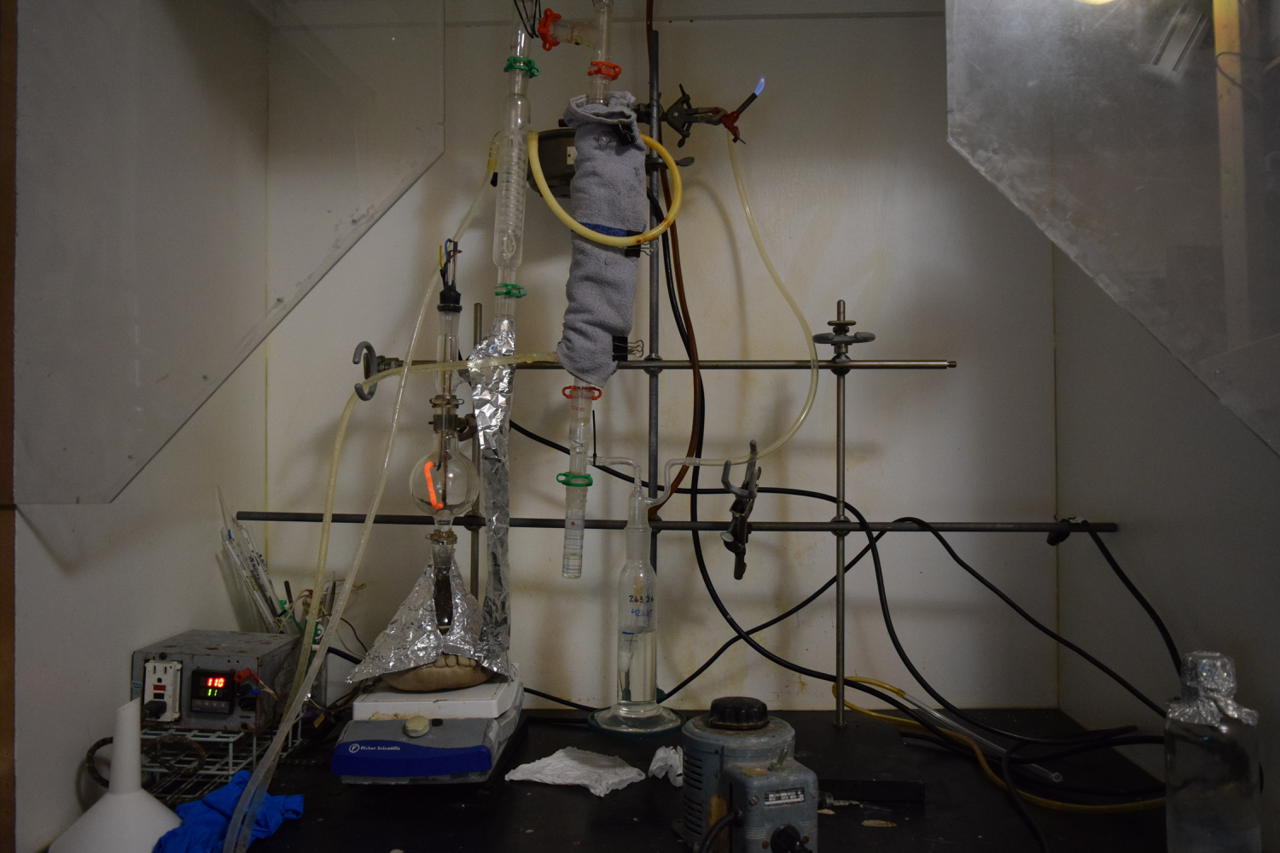

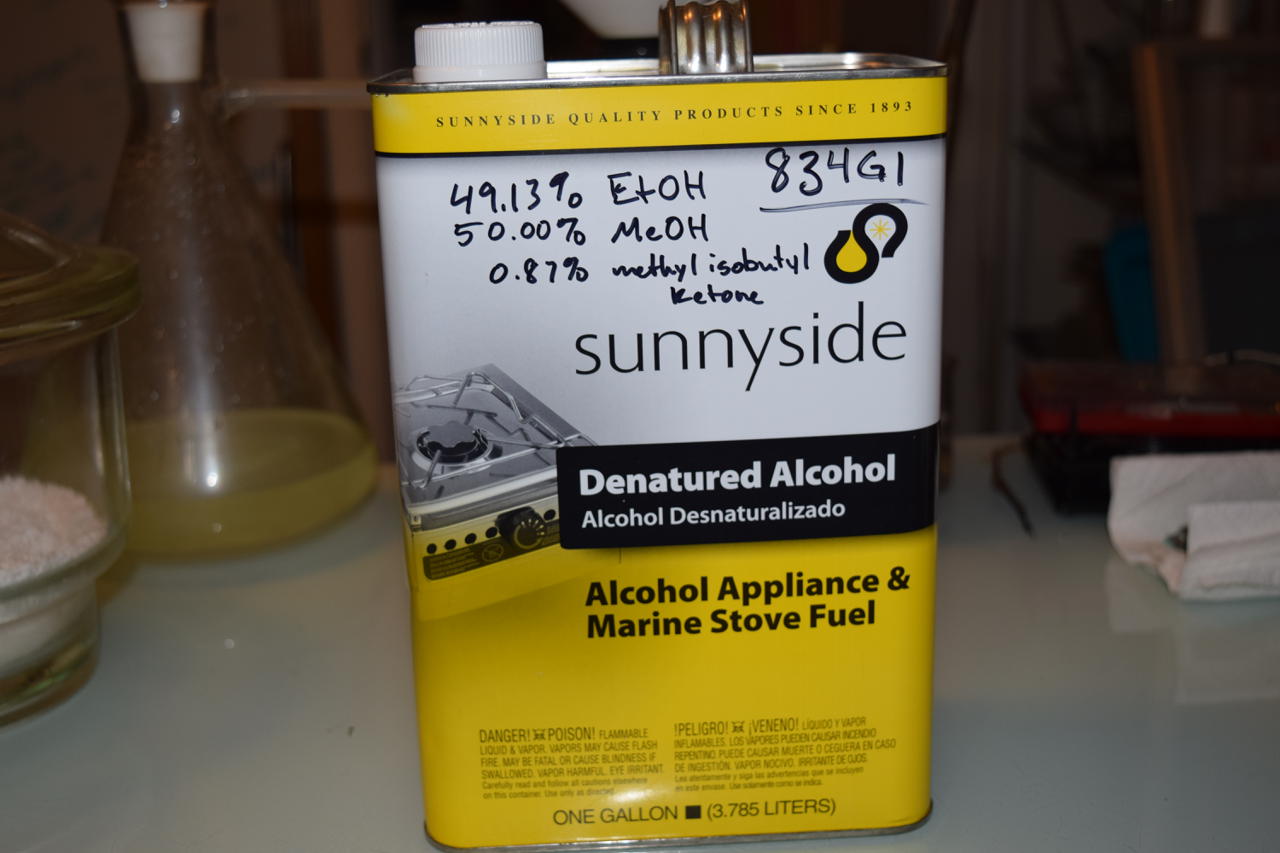

I made some trimethyl borate.

- 650 ml methanol

- 247g boric acid

- 100g concentrated sulfuric acid

Reflux for 30 minutes then fractionally distill the 65C azeotrope of 3:1 trimethylborate:methanol over 6ish hours.

I also made some strontium nitrate.

- 14.7g strontium carbonate (1/10 molar scale)

- 19g 68% nitric acid

28 Oct 2020

Holy hell Ubuntu can be terrible.

For some reason my computer stopped booting. Since the screen is still broken, I’ve been booting to an external monitor. Sometimes the screen doesn’t display anything (who knows why) so I just type in my BIOS password and LUKS password without seeing the prompts and that usually works. This time, however, it just hung on that Ubuntu fuchsia screen for hours.

Briefly, here is the steps I had to take to fix the issue over two days.

Eventually I figured out that grub was having issues again. So I removed the hard drive and attempted to boot to it using a different computer. It wouldn’t boot there either.

I thought the drive was failing, so I mounted it as an external drive and copied all my valuables to another drive. I already have a duplicity backup, but it doesn’t hurt to have more copies.

I tried to fix grub using the command line in a live ubuntu flash drive boot (boot-repair), but the computer I was using didn’t have an EFI boot ability so that failed.

I then put the drive into an old laptop that had EFI boot and succeeded in repairing grub. Then I could boot without issue in the old laptop and I used that setup for a few days.

Unfortunately, when I relocated the drive back to my new laptop, the thing wouldn’t boot again. After several attempts, I remembered that the Asus X550VX has some necessary boot flags. So I proceeded to try those flags as I’ve done in the past… no good.

I was still getting errors.

After a lot of searching, a few boot flag changes, and some apparently miraculous events, my laptop is back in service. Minus a screen of course. I have updated the laptop page with the new info.

Cider

I’m making some aged spiked cider a la Instantly Age Alcohol | The Though Emporium.

22 Oct 2020

The cyclohexane did not freeze out. Kinda figured. Looks like it is time for some intense fractionating.

For some reason my acetic acid fraction has a head temperature of 99C. Either I have pure water (unlikely) or my $3 thermometer is wrong (more likely).

In any case, it took 15.5 ml of 100mM sodium carbonate solution to neutralize 0.2ml of the total 150ml result giving a concentration of 7.8M or about 46%.

Not too bad.

21 Oct 2020

Wow, that was fast. I ordered a TwoTrees Sapphire pro 3D printer on AliExpress on Monday. I didn’t even know it had shipped yet, but I am now the owner of a 3D FDM printer. At least the kit for one.

I would like some heptane for chemistry. It is a pretty useful recrystallization solvent. I have some isoheptane which I obtained from starter fluid, but that isn’t the same.

Camping fuel seems to be a cleaner starting petroleum derivative than gasoline. Campfuel doesn’t have anti-knock additives or as many carcinogens.

Coleman camp fuel contains:

| component | bp | mp | density |

|---|---|---|---|

| cyclohexane | 81 | 6.5 | 0.7739 |

| nonane | 150 | -54 | 0.718 |

| octane | 125 | -57 | 0.703 |

| heptane | 98 | -91 | 0.6795 |

| pentane | 36 | -130 | 0.626 |

I’m curious whether the cyclohexane fraction can be removed by freezing. It will probably remain dissolved, but I’m going to try it anyway.

I have some off brand camp fuel that has been sitting in my outdoor shed for years. Probably all of the pentane has evaporated by now. Anyway, I added the 450 ml that remained to a 1L flask and set it in the freezer.

I am also fractionating the ketene lamp product.

I had some backflow issues so the tar flash got mixed with the product. So I just poured both into the boiling flask for fractionating.

At some point I would like to determine the number of theoretical plates my stainless steel washer mini-column has.

I really need to do some maintenance on the lab chiller. Algae build up is a constant problem. I haven’t checked the hot loop since I filled it. There isn’t enough capacity to fill my leibig condenser, so I have to manually add water each time I connect it.

20 Oct 2020

I’m assembling a plague doctor costume for Halloween. Masks are super cheap on Amazon for some reason. I bought one for $16.

Pork Pie Hat

- https://www.instructables.com/How-to-Make-a-Leather-Hat/

- https://tombanwell.blogspot.com/2010/01/steampunk-leather-top-hat-tutorial.html

- https://sites.google.com/site/leatherlearn/Home/tophat

- https://www.instructables.com/How-to-Make-a-Leather-Top-Hat/

- https://www.youtube.com/watch?v=qkNI70CD47U

- https://www.youtube.com/watch?v=t5u6hAlj-Qg

- https://www.instructables.com/How-To-Make-A-Leather-Bushcraft-Hat/

My head is 22.5 inches in circumference. The simple pattern I am using is for unshrunk leather and for someone with a larger head than me.

I also want a larger brim than is shown. Something closer to this.

After testing a few different stitches between the circumference and hat top, I decided that the fabric wasn’t stiff enough. I have some lightweight fusible interfacing that I might try doubling over with the glue side facing outwards. This gives two separate layers of stiff material: the liner and the faux leather.

I stitched for hours and hours. My fingers hurt.

19 Oct 2020

I just spent more money that I am willing to report here.

I have renewed interest in the clinical trial alert system. The basic idea is to develop a platform for clinical trial participants to be notified first when new trials are posted.

Competition among healthy clinical trial participants is fierce. Clinics will routinely screen two or three times as many potential participants than will ultimately be accepted. This excess is to account for people failing to meet the health requirements and dropouts. Apart from a few outliers, admission is on a first-come, first-serve basis.

Thus, there is a need to be alerted to new trials before anyone else.

I envision a website that allows you to subscribe to the alerts (by email or text) for a fee. New trials are found using web scraping and added to the database. The site also provides generic information about each company (amendments, average payout, etc.).

So first things first: find some websites and start scraping.

18 Oct 2020

Well I’m back home again.

Shortly after my arrival at the clinical trial, my laptop screen was damaged. I had intended to do some programming and writing during my stay, but was unable. Fortunately, a replacement screen is only about $70.

I just watched a video on making copper and silver sauce pots. The marketing suggests that the heat conductivity of copper and silver are high enough to negate the need for stirring.

Silver is chemically resistant, moderately abrasion resistant, and extremely heat conductive. Copper is not chemically resistant, more abrasion resistant than silver, less heat conductive than silver. Copper is, however, significantly less expensive than silver.

The cheapest high performance pots are made with tin lined copper. The tin lining must be repaired over time. Using a silver lining adds chemical and heat resistance and lengthens the lifetime, but still requires touch ups. Fusion is preferred to plating due to the thickness of the lining to prolong lifetime but also adds cost.

I wonder if the thermosiphon technology could be used instead. Basically a sealed flat copper cavity with a working fluid (probably water). Kind of like a double boiler but sealed.

That would result in huge gains in heat conductivity, near immediate cool down, and a built in temperature limit. No more burning.

Diamond has an order of magnitude better heat conduction than silver. It is also extremely chemical and abrasion resistant. I am unsure of the thermal expansion, however. That parameter must match for good adhesion. Diamond also burns, so the entire pan can’t be made from diamond (as if someone could afford that!).

So… copper heat spreader coated in diamond. Or perhaps more practical for my current level of tooling: copper heat spreader with a silver plating.

08 Oct 2020

So here I am again. Phase I clinical trial. Gotta earn that money. 4K in 10 days. It would be perfect if only I didn’t have to go through caffeine withdrawal.

You definitely meet some interesting characters in here.

02 Oct 2020

Over the last few days I have reduced my caffeine intake by half in order to meet the zero requirement by 06 Oct.

This sucks.

29 Sep 2020

Finished the images processing python script (source raw).

It isn’t quite finished. I’m not sure about the need for thumbnails. I would also like to autogenerate a complete list of images, but I think that will be a separate task at website build time.

28 Sep 2020

Ranted some more on AI stuff.

Some plant stuff.

27 Sep 2020

I came to the conclusion yesterday that my work with ontologies is inadequate. For even if I manage to finish my component ontology that I have worked on for a month now and am only 10% finished with, I still have at least a dozen more ontolgies to finish to completely capture the project.

So ya. I need a better way.

Enter AI… again.

mHTM again

I really like Hierarchical Temporal Memory but its implementation is convoluted.

MathHTM simplifies the spatial pooler algorithm and adds some Scikit-learn features.

I would love to be able to combine the core features of HTM and Adaptive Resonance Theory.

26 Sep 2020

Finally got a hold of the domain for my namesake <elijahdunn.com>. I’ve been waiting for more than two years for a squatter to relinquish the domain. I don’t know what I will do with it.

Ya know what the problem with any form of external knowledge storage medium (books, audio recordings, videos, deep learning AI, ontologies, etc.)?

They are all static.

They are not completely static: some AI algorithms have “on line learning” that allows them to change with exposure. But in all cases, there is a clear separation between learning and usage.

Or, perhaps, more precisely: A storage mediums usefulness is proportional to the overlap between learning and usage.

Maybe that is only the case in my perspective–one of imperfect knowledge. I can imagine a system that would know everything and be infinitely valuable despite not needing to learn.

Images

I have a lot of video and images that go along with each project on this site. I would love to stop managing them by hand and offload some of the work to python.

Each project has a static website page, a website image folder, an image originals folder, and a set naming format for each. The current naming convention is [project name]-[image title] but I’m somewhat torn about using datetime in the filename.

The images from my DLSR are much larger than necessary for a website like mine (6000 x 4000 px). So the images need to be shrunk and renamed but the original size must be maintained.

So currently the process proceeds as follows

- transfer all photos from camera memory card to

media/originalsfolder - sort photos manually into

media/originals/[project-name]folders - delete duplicate photos or poor shots

- adjust color (auto color enhance + auto white balance with GIMP)

- rename photos manually by describing their content

- run

python img.pyto prepend project names and move smaller image files to website folder

TODO: write script to auto color and white balance images (https://www.gimp.org/docs/python/index.html).

25 Sep 2020

I wonder if there are any instances of truly self-made people who have a genuine impact comparable to Tony Stark? I’m sure it is a continuum, but my point is that the characteristics required for money making are generally negative.

19 Sep 2020

The symmetries that are most important for mechanics are rotational and translational. Helical symmetry is also quite explanatory, but it is a combination of translational and rotational.

Symmetry is hard. Symmetry Category | Wikipedia

18 Sep 2020

Now the question is… How do I partition automorphisms?

The allowable movements that result in indistinguishable object orientation? The degrees of freedom that uniquely determine an object’s position? Planar/axial automorphic? Reflection, translation, rotation? Discrete/continuous symmetries? Number of orthogonal, planar projects/views necessary to fully characterize an object? Number of dimensions necessary to describe an object?

- cross sectional automorphisms

- uniform translational cross section

- uniform rotational cross section

- uniform helical cross section

Loci of Orientation

A rigid body requires six loci of orientation to define its position with respect to the local coordinate system: three linear and three rotational. In objects with symmetry, some of those loci give rise to indistinguishable object orientations. A perfect homogeneous sphere needs only x,y,z coordinates since rotation about any axis gives the same object. Hence, a perfect sphere has three loci of symmetry and three loci of orientation.

This excludes (extrinsic?) Euler angle representations. They may be mathematically complete, but not very intuitive since they combine linear and rotational movements into a single rotation about a point.

- 3 loci of orientation (three loci of symmetry)

- bearing balls

- 2020 square aluminum extrusion

- 2040 rectangular aluminum extrusion

- friction-fit pulley

- cylindrical shaft

- 4 loci of orientation (two loci of symmetry)

- 5 loci of orientation (one loci of symmetry)

- continuous

- roofing nail

- discrete

- hex head bolt

- 6 loci of orientation (nonsymmetric)

- weld bead

15 Sep 2020

I learned recently that some people value certainty more than truth Paulogia Video.

This distinction hadn’t even occurred to me.

Ontology

The key is to determine the physical qualia that give rise to a function, not to describe the function itself.

For example, wheels have continuous rotational symmetry therefore they perform the wheel function. The wheel function does not describe the wheel, only its rotational symmetry.

A screw functions because it has helical symmetry. A linear rail functions because it has translational symmetry. And so on…

This type of partitioning based on physical qualia is much more suited for describing the function of a component in a system because if an object shares the same qualia it can be used in the same way.

For example, a cylindrical hardened steel shaft can be used to transmit rotational energy. So can a nail. In some cases, a nail can be used as a shaft (as is common in pinewood derby cars). If the typical classifications of “power transmission components” and “fasteners” was used to distinguish between shafts and nails, the two would not be easily substituted.

The goal of this project is to link substitutable parts more easily.

13 Sep 2020

Attempting to decide what the ontological difference between various joiners is: adhesive, glue, weld, fastener, and binder. This is my life now.

For the record, the difference is the physical location of the joiner: intermixed, exclusively between, and through. Glue, weld, and braze are all types of adhesives that are located between joined objects. Fasteners are simultaneously within and without a joint (i.e. through). Binders are semi-homogeneously intermixed.

This differentiation puts hot-melt glue in the same ontological category as welding and brazing.

There. Ontology XP +1.

12 Sep 2020

Started some seeds today.

11 Sep 2020

Converted a closet into a garden using a Samsung strip light. It turned out better than I thought. I previously used three COBs to illuminate a small area. The strip is much nicer.

I drilled and tapped a few holes in a strip of aluminum then wired (literally iron wire wrapped) it to an iron pipe clothes rack.

I currently have some ICS95 cacao cuttings in the mist propagator. I don’t know if any of them will survive which is really upsetting. They look much more brown than when I started them in some vermiculite-coir media on Sep 3rd.

I should have kept them in a humidity dome from the start. Dammit.

10 Sep 2020

Second run of the ketene lamp today. This time at a higher throughput and waste gas burner. The flame burned with a ~3cm flame. Start at 1430. Ended at 17:55.

Acetone pot temp was 105C. Element voltage was 25V and 6.2A. The power going into the variac was 180W so about 86% efficient. That’s about $0.02 per hour to run the element. Let’s say double that to account for heating the pot and cooling the water. ’Round up to $0.05 per hour or about $10-$20 per liter of pure acetic acid. That’s not too bad. Of course, time is the real killer here.

The heating mantle I am using has a maybe 20% duty cycle. At a rated power of 270W, that’s about 50W RMS for heating. My little thermoelectric chiller is stuggling a bit with cooling. The chiller water remains below ambient, but just slightly. So now we know that the chiller can handle at least 200W.

I wonder if plasma pyrolysis could be adapted to ketene production. The research seems to be focused on syngas production from solid waste.

09 Sep 2020